You can’t simply do Takt Time production without some specific crawl plan. If you do not prepare well in this first phase, you will run into a lot of problems and even increase the amount of waste in the conversion process.

The top advice in adopting Takt Time for managers is to take the time to seriously plan and put things in place before making any changes. The first thing they should do is string the related data to standardize it into a unified database for use in the analysis:

In addition to the above factors, you can find many other characteristics that you can use to help improve the Takt Time production planning and implementation process.

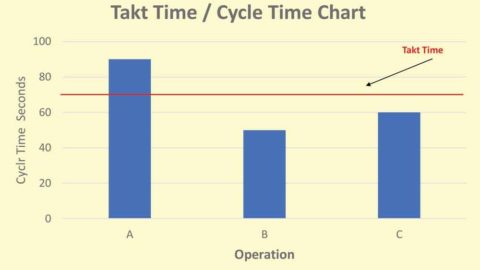

Through establishing a production scenario that is integrated with customer needs, Takt Time provides the organization with an efficient tool to measure, control waste and improve productivity. Instead of focusing on productivity output (number of products per hour or minute). Takt Time aims to produce products on schedule according to customer requirements and to create a smooth flow throughout the entire process with the same production rhythm. It also plays a role in keeping rhythm and balancing production to create a flexible pull system.

Source: Kaizen News