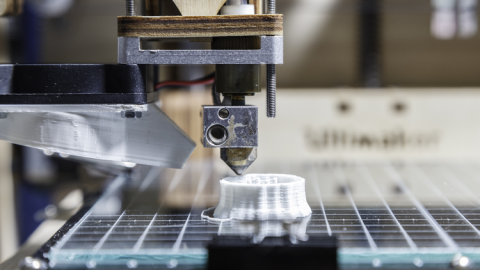

The manufacturing of accessory materials (AM), known as “3D printing”, has become a very widely used industry in manufacturing, with the ability to create highly detailed and complex parts. High accuracy should appeal to a number of other manufacturing industries.

The study explores 162 managers and executives in a variety of roles and from many manufacturing companies along with their experience in the world market, the challenges and trends of 3D printing in industrial production. .

- 40% of all answers are using 3D printing on a full-scale production scale, almost double the previous year.

- Two-thirds of companies report they have more than doubled their use of 3D printing on an industrial scale.

- 47% are using this technology to print component details in manufacturing, up 17% from 2018.

- 58% of respondents say cost reduction is the main factor for using this technology, while 61% of respondents say that large scale 3D printing is applied to reduce production time. Moreover, 59% of businesses believe that the application of new technology will benefit them by diversification, while 59% of enterprises want to speed up the production of parts and 51% want to achieve high efficiency. higher yield.

So why is this technology so powerful? Here are some reasons:

- Producing by 3D printing technology without embryo and without wasting materials.

- The process of automation, people do not interfere much, optimizing human time and labor.

- Easy to design and shape.

- Allow users to create complex shaped products with ease.

- Solving the problem of concentrated production, eliminating difficulties in arranging workshops and factories.

- 3D printing with the ability to adjust the level of material density within an object structure, able to customize according to product requirements, create products with a light structure, solve the problem of unnecessary residual weight , meet the diverse needs of the product.

- Easily check designs in terms of form, function and purpose of use correctly, change design drawings in a flexible and inexpensive way. Minimize design errors when put into production.

Using 3D printing technology, you will completely proactively bring out the best quality products. You can create products from design drawings quickly at the lowest cost, and completely change products as needed. You can also create product samples to test and evaluate before putting into production without cost.

Blake Teipel, Essentium director, said: “We need to put great faith in the breakthrough in the production of industrial scale accessories, and so our customers can benefit from the changes brought about. the technological breakthrough like this ”.

Productivity and Quality Office