In many cases, the buyer verification of the “first test pieces” is actually not an entrance test (FAI). Many other Asian manufacturers prepare them in a model room, rather than in cutting and sewing workshops.

The technician will not only run a functional test, but also perform a visual examination on a microscope to receive any problems that indicate the problem of the process.

When does the non-meaningful entry exam confirmation?

If a long time passes until the first completed item rolls off the line and if a long setup time is needed at some step, that may not be practical.

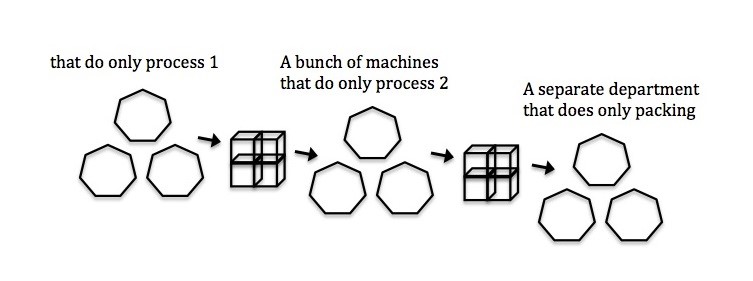

Basically, this type of manufacturing process cannot be highly effective:

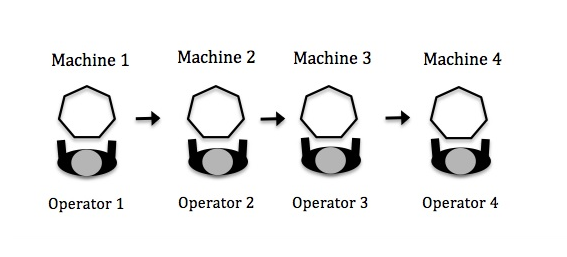

And this type of production process setup will make it easier for your business to implement FAI:

The next step, if you feel that you will benefit from taking the entrance test, you have 3 options:

1 – Have your supplier do this in their factory

Advantages: no additional costs for your company; Buy from within their organization

Cons: The report may not exist or be poor and may be generated

2 – Implement them yourself at your supplier’s facility

Advantages: direct confirmation that it’s actually done; You learn about your supplier process

Cons: scarce resource consumption

3 – Work with a quality assurance company like us to do them for you

Pros: confirms that it’s actually done, with clear reporting; Easy to book and dispatch a technician

If a manufacturer is about to start creating a new product and if the volume is expected to be high, it makes more sense to implement a comprehensive FAI manufacturing process system. Perform FAI successively through multiple stages until it can be demonstrated that this new product can be produced at the desired speed and quality level.

Conversely, if the production batch is very small and if the manufacturer is quite accustomed to creating that particular product, it may not take more than a few minutes to check and confirm the entry test. This is also one of the most outstanding benefits that FAI brings to businesses.

Productivity and Quality Office