Fast food companies have relied on the rapid evolution of technology to bring consistency across their entire business model, and so should manufacturers.

Bloomberd Business Week explains an example: “All the Taco Bell, McDonalds, Wendys, and Burger King stores are both a form of miniature factories where managers can oversee a lot of their employees and equipment. They plan, change, track inventory and supply chain; they oversee the line and generate large volumes of quality controlled products, which bring them in revenue from 1 to 3 million dollars per year. All stores have customers willing to show up right in front of their premises 24/7 to buy products.”

In the economic blog Seeking Alpha it said: “Think about the times when the automaker changes the design of the car. Certainly a factory can make several models on a common background and might change that pattern every year. But those changes are usually small changes, while big changes are less likely to happen. As for fast food, on the other hand, competition is intensified by offering special and short-term services. Therefore, the design of new products must be limited by the production process while still needing to bring customers new experiences.”

Here are a few principles inspired by the fast food business model that producers can apply to their business (ValueStreamGuru.com Blog):

Product and process standardization: The Big Mac is the Big Mac no matter where you buy it, this emphasizes on providing reliable and highly standardized products, processes production is unified. This is something fast food companies have perfected over the years.

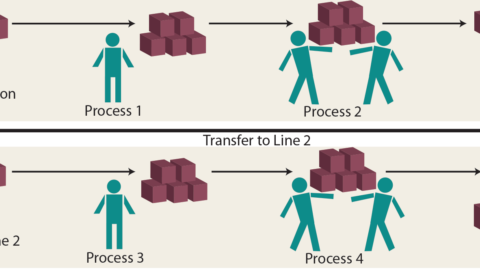

– Applying production methods: Each different facility has its own separate working areas to create a complete product, allowing maximum efficiency in each unit.

– Use “Pull production” (Just InTime – JIT): That allows the fastest product deployment as soon as the need arises, while maintaining the production of other products to ready to release.

– Optimization with lean manufacturing process: Optimizing usable area on a floor. Fast food restaurants often have very limited production areas but their output is very large, which means that their space is maximized.

Productivity and Quality Office