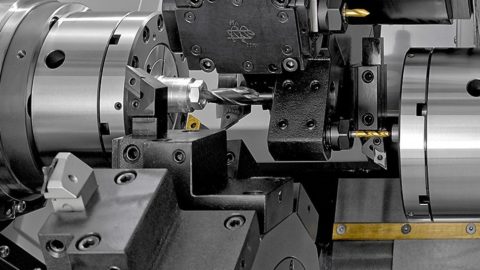

Unicut Precision's Miyano BNE-51MSY lathe

With the motto: “Differentiation for success”, Mr. Nicholson soon decided to adopt a different business model by approaching original equipment manufacturers, analyzing their main cost factors, which Check the ability to restructure parts for more efficient production, set desired cycle times, identify machine tools needed for machine parts during that time, and then recommend implementation necessary capital investments, complying with manufacturer’s commitment for a term contract, etc.

Unicut Precision is currently actively developing new technologies instead of scaling production, as transferring designs and manufacturing processes to original equipment manufacturers can help the company make more effective use of its resources.

For the machining of large diameter parts, the 51 mm Miyano is priced on the same level as the most modern 32 mm Cincom slider. With the goal of finding the right production method, the use of Cincom sliders gives Unicut more advantages, typically: greater capacity, more flexibility; higher spindle capacity, leading to increased productivity; cycle time is equivalent; easy access to set up, despite the compact machining area; and Mitsubishi’s controls support overlapping machining, whereby three tools can be cut at the same time, one facility for use at the Welwyn Garden City facility to enhance productivity.

On the other hand, a second pair of Citizen Machinery UK Miyano BNE-51MSY rotary lathe centers were installed at the Unicut Precision plant, Welwyn Garden City. This enables the company to produce approximately 1,000 very high precision parts without having to touch the machine by simple means of including macros in the program to automatically compensate the tools after some components have been produced. Tolerances down to ± 2µm can be maintained and a surface finish is described as perfect.

Mitsubishi CNC systems are fitted to Miyano and Cincom lathes due to its versatility and ease of operation using drop-down menus and comprehensive graphic support. Citizen’s Alkart Wizard Offline Software helps ensure that work goes into production quickly.

In addition, to ensure 100% quality control of output products, Unicut Precision has used resource management planning (MRP) software. The functions of the MRP software include inventory inventory, purchase management, production forecasting, raw material cost calculation, purchasing planning. Unlike ERP, however, you don’t need access to financial management or CRM software features. As a result, you can have more control of the production process without trying to integrate as comprehensive as ERP programs. In addition, ISO 9001 and PPAP are also other effective tools to help Unicut Precision ensure product quality.

Productivity and Quality Office