Application of ultrasonic welding technology in production

Today, the machining industry is difficult to use a lot of different welding techniques, each of which has its own strengths but in general is based on the structure of the materials used. One of the most modern methods available in this area is the method of ultrasound.

Ultrasonic welding uses the vibration intensity of a superhumidifier to attach two components that may differ in structure. One of the biggest strengths of ultrasonic welding is that it can be used for other metallic materials like plastic. By applying the vibrations of the ultrasonic duplex to the weld, the vibrations with high frequency cause the material to melt and stick together. The commonly used wave in this technology is high frequency duplex with frequencies between 15 and 40kHz. Because these ultrasonic welding devices can focus on a certain point, the welding with this technology is extremely accurate.

Composition of ultrasonic welding technology

Ultrasonic welding machine was created to convert electricity into mechanical vibrating bars. The microcontroller reads the temperature and controls the output temperature correctly. Some other components:

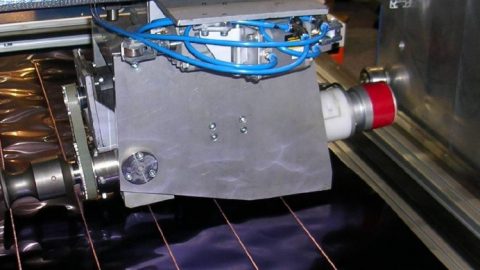

Welding materials should be held in place by a support. Air compressors are often added to welding machines so that the pressure of the compression wave can be transferred to the material through the channel.

Ultrasonic waves are applied in small amounts and continuously into the material, the intensity of the vibration will cause the material to vibrate, the vibration frequency is larger but the amplitude is only about ½ mm, causing materials to occur. close together and create heat to melt. This principle is similar to when you rub your hands together faster and more friction will get hotter. However, the frequency that the ultrasonic welding machine supplies so that it can melt the metal is not visible to the naked eye.

Benefits of ultrasonic welding machine:

Disadvantages of ultrasonic welding machine:

Practical applications of ultrasonic welding technology:

Ultrasonic welding is used in many areas of industrial manufacturing. One of the most amazing applications is the welding of signal cables. Ultrasonic welding is also used in health, automobile manufacturing or housing construction applications because ultrasonic welding does not increase the weight of the material like other welding methods but still retain its strength durablility.

Although ultrasonic welding technology has been studied since the 1940s, this technology still has great potential for future development with methods of making cleaner, stronger welds between different materials.

Productivity and Quality Office