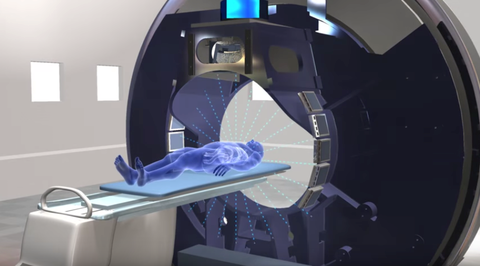

RefleXion Medical has completed a prototype of the biologically guided radiotherapy device and hopes to eventually make a clinic-ready device (Source: Fiercebiotech)

Quality 4.0 is the convergence of new technologies that create a modern manufacturing landscape. Similar technologies are being used to design and deliver products. What does this mean for medical device manufacturers?

For starters, the digital transformation trend has helped identify Quality 4.0 strategies to eliminate the dependency on quality management systems and processes based on the type of documentation. different. Changing quality management practices from manual systems helps reduce errors, silos, collaboration barriers and traceability issues.

Moreover, digitizing and automating design and manufacturing processes allows small and global companies to expand their design and supply chain processes quickly. For example, such a company, RefleXion Medical, a leader in bio-guided radiotherapy systems for cancer treatment, knows that they need to implement a linked quality management system (QMS). The connector is fully expandable to support the digital transformation path and improve compliance. They require a flexible platform that can grow with their team, products and paths throughout the quality compliance process.

Newer quality standards in the supply chain

To accelerate products to market today, medical device manufacturers rely on distribution and supply chain groups, including contract manufacturers, design partners, and suppliers. accessories. Companies that embrace new technologies and cloud-based systems understand the unique benefits digital transformation technologies can bring to device manufacturers, product requirements, product capabilities and regulatory compliance goals.

In the field of life sciences, digital treatments, medical diagnostic devices, implants and disposable devices are just a few of the devices that try to be trouble-free while provide higher throughput and maintain compliance.

Integrate with connected groups

Using a connected central quality management system (QMS) or more products can help meet the needs created by Quality 4.0 trends. As product complexity increases with AI, IoT, robots and related 4.0 technologies, quality teams must have a unified system to identify issues, audit issues and address issues. quality breakdown. This ensures that complex, complete product design including electrical, mechanical and software components are contained within a single system.

The platform enables complete, quality connection with corrective action records and provides increased visibility and transparency as teams collaborate through each stage of product development and introduction.

Productivity and Quality Office