After finishing the process of researching and building a technology investment plan, managers should note the following factors when starting to apply:

Ensuring efficiency in material handling

Material handling often consumes a lot of time and money, so managers need to respect and devise strategies appropriately to achieve efficiency in this area. Carrying out the movement of material components to the handling area in an organized manner is one way to reduce operational costs in the welding process. If most of the welding in the plant’s line is done in a centralized area, the company should invest in equipment and technology to make that process work as best as possible. Because moving materials back and forth in many stages at many different positions leads to wasting a lot of time and money for businesses unnecessarily.

Reassess your process

The second most important factor to study while evaluating welding performance is the operating index or the correct arc at the right time. The study of arc welding timer shows that the operator only spend about 30-40% of the arc time for welding. Non-weld operations such as material handling, surface cleaning or heating are unavoidable (although these steps are not important). The truth is that 60-70% of the time it takes to deal with non-weld processes does not bring any extra profit to the product, so these steps need to be eliminated or minimized. possible.

Improved welding process

It is necessary to study more factors that affect the quality and performance of metal material processing such as the mode transducer, wire feed speed, travel speed, wire diameter, etc. For example A metalworking shop is welding the material with a short arc and uses a 75/25 protective gas mixture, if they switch to gas spray mode transfer, it will Efficiency is much higher.

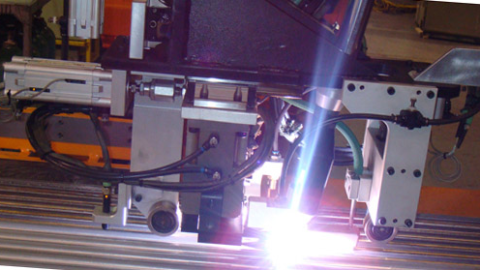

Add an automatic system or integrated robot

Applying the advancement of technology has become essential to an industrial environment that involves many repetitive steps and needs to be done at the highest possible speed. Automation technology is an unprecedented solution to improve productivity and quality in the metalworking and machining industry.

In general, there are many methods for mechanical machinists to improve their welding process. In particular, many of them are only about coordinating internal processes or standardizing investment items. With the advantage of having no (or very little) investment costs but the benefits that are significant, there is no reason for you to refuse to try the methods at your organization.

Productivity and Quality Office