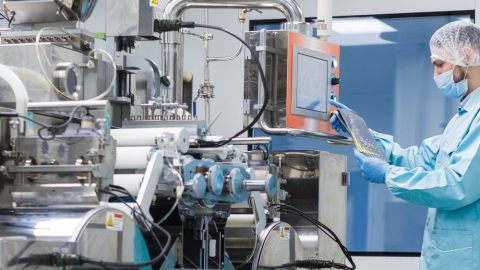

Illustration (Source: Internet)

For pharmaceutical industry, product quality is always a decisive factor for competitiveness. The more businesses improve their quality standards, the more difficult and expensive it will be to continue to improve. As a result, these businesses have spent more and more effort and effort to create added benefits and added value to the patients, leading to a reduction in overall return on investment. In other words, the most costly and profitable improvements are always made first, and then it becomes more and more difficult to keep improving.

One way for businesses to get out of this situation is to apply 4.0 technology applications to operate more efficiently, make more data-driven decisions and use predictive analytical tools smarter.

At many large pharmaceutical factories today, the process analysis technology (PAT: Process Analytical Technology) has been discussed and piloted at pilot scale in leading pharmaceutical corporations and companies.

Although not yet widely applied on a large scale, the widespread adoption of these technologies is now only a matter of time. There will be hundreds, even thousands of connected smart devices, or as IT terminology, are embedded into pharmaceutical manufacturing processes and technologies to collect data. “Real Time” data and information, for example in factories operated by SCADA (Supervisory Control and Data Acquisition) systems, to replace the performance of quality checks according to traditional.

Here are some benefits that pharmaceutical businesses can gain by applying 4.0 technology to production:

Manage and store data more effectively

Data management applications such as Big data, cloud computing, Internet of Things (IoT) have affirmed their position not only in the pharmaceutical industry, but also in the whole industry in general. IoT through sensors capable of recording both data accurately in real time, greatly reducing errors in the analysis process and saving human resources for this activity.

Thanks to Big data technology, a large amount of electronic data about the specifications, designs, production status of pharmaceuticals will be created and stored in digital data warehouse instead of having to build warehouses Data storage. Accordingly, businesses can significantly save storage costs, search and search data in the shortest possible time.

Not only that, through good data management, the process of data analysis to make improvements also becomes more convenient. We will continue to explore this issue later in the article.

Productivity and Quality Office