T & R Precision is a mechanical machining services company based in Foulridge, East Lancashire, UK. With extensive industry experience and highly qualified staff, T & R Precision has become one of the few regional manufacturers and processors capable of supplying precision mechanical components for the aerospace industry.

In the field of precision engineering, product quality is the most important factor determining the competitiveness of the business. Technical challenges as well as the need to test professional skills from customers also put a lot of pressure on manufacturers such as T&R. To solve the above problems, the management board The company decided to radically change the way of operating and managing the production process through the “Digital Transformation”.

Digital transformation is a long-term process. Currently, infrastructure constraints such as network connectivity or outdated applications that are no longer suitable for new systems affect the digital transformation activities of 75% of businesses. Karma. Surprisingly, 99% of the major brands surveyed confirmed that they are investing in their own infrastructure and ecosystems including cloud computing, Big data, data analytics, Artificial intelligence and enterprise solutions.

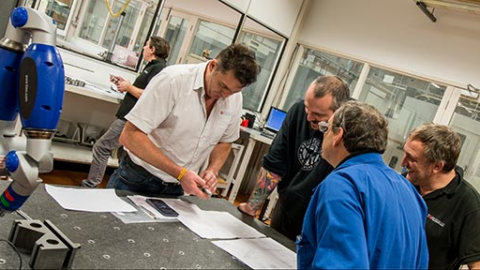

The major advantage of T & R in digital transformation is a modern infrastructure system with highly compatible machines. For example, the company recently invested in a tailor-made solution to fully automate the machining system by applying new hardware and software solutions to a 5-axis CNC machine. It is integrated with the quality control department, provides real-time monitoring for the management team and allows every order to be tracked and integrated into the supply chain. On the other hand, given the size of a small and medium enterprise, digital transformation at T&R can be done much faster and simpler than for a large enterprise.

Representative of Made Smarter – digital consultant for T & R, Mr. Donna Edwards said: “Data and analysis are at the heart of the 4th industrial revolution, so I am extremely pleased when There are many small and medium manufacturers who are looking at data at the heart of their own digital journey”.

At T&R, a virtual space network was established as soon as the digital infrastructure was ready. In this space, the devices will share data with each other and with the central management system, receive operation commands from the central management system to operate. Thereby, the sensors can send data about the state of the machine, the process time as well as the failure log, etc, continuously in real time. Data is also stored and analyzed with Big data for evaluation and future improvement.

(To be continued)

Productivity and Quality Office