Number of errors dropped significantly after improvements

Recently, Trong Phuc Trading and Trading Co., Ltd. has completed the program to apply LEAN lean management tools under the support and advice from the Technical Center for Standards and Quality Measurement 3 (QUATEST 3) within the framework of the national program “Improving the productivity and quality of products and goods of Vietnamese enterprises by 2020”.

Known as a unit with many years of experience in the field of animal feed production, Trong Phuc Trading and Production Co., Ltd. is always looking for methods to improve productivity and product quality. Through the typical successful application of lean production tools worldwide, the company’s management decided to pilot this tool. In the first phase of the program, consultants proposed many wastes present in the line of Trong Phuc company, such as:

– The performance of the device is not high

– The factory scene is not neat, the production area tools have not been screened

– The area of the material shelf is not clearly noted, it takes time in finding the necessary tools.

Based on what the survey was, the advisory group discussed with management to agreed appropriate solutions to help bring about positive changes in production activities. Specifically, the solution can be mentioned to estimate the production time according to each order; determine the information of the supplier of raw materials for pre-preparation as planned; identify information with the production department to assess production capacity; determine maintenance department information if necessary; hold a meeting when the plan is implemented production to reduce the load of machine down time beyond the plan.

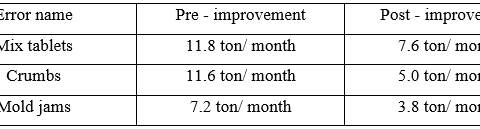

Besides Lean, Kaizen and 5S are also supporting tools used by the innovation team with the goal of improving productivity, quality in a long-term and sustainable way. The above tools are intimately related and always complement each other in the application process. For example, 5S improves the working space in the factory, making everything in a consistent, easy-to-find, easy-to-find and standardized location for tools. This almost eliminates the entire waste of travel time and waste of human resources. In addition, the Company has also established and implemented the Kaizen method. Under the guidance of QUATEST 3 experts, the factory prioritizes solving errors and staff and crumbs, while standardizing working steps, organizing skills training for members of production organizations and equipping some cleaning tools, lighting systems. Thanks to this improvement, the rate of producing errors has decreased significantly.

In general, the application of innovation tools not only brings economic efficiency, but also helps Trong Phuc companies maintain an improved culture, build positive habits for all employees as well as management. Although the objectives set out when participating in the program have been achieved, the whole company needs to constantly strive to maintain the above achievements and move towards higher goals in the future.

Productivity and Quality Office