APH3G Company was formerly Arthur Pollard Hollings, a manufacturer with 60 years of experience in the field of vacuum casting, fiberglass mold manufacturing, machining, prototype assembly and equipment fixtures, machine parts.

To solve the problem of inventory due to errors, APH3G decided to invest in an intelligent production line with high precision. These include new equipment integrated with a modeling system (CAD) and computer-assisted manufacturing (CAM). After the raw design created from CAD is analyzed, calculated, checked, the data will be imported into CAM software to set up the machining process. Ultimately, the CNC machine tools are the equipment that executes that process.

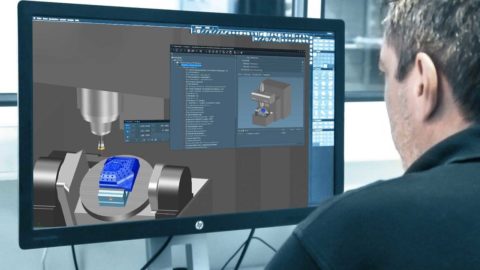

APH3G used Tebis CAD / CAM software from Tebris company for their outsourcing activities. This software allows the operator to construct 3D models of the workpiece, and then store these designs in the process library. Configuring the Tebris also means building a design that’s constantly optimized through many trials. Therefore, local defects are minimized, and factors affecting production cycles at APH3G will be recorded for future corrections.

APH3G Director Andy Hollings explained why they chose Tebris: “When we looked at the many different companies and packages they offer, we found Tebis’ software to be very user-friendly. and our engineering options perfectly fulfilled our requirements. ” He also added: A software with high compatibility and easy-to-use interface will help the company significantly save costs and time in operator training, and lower the recruitment requirements for qualifications. expertise for the position. This is also one of the top advantages of APH3G’s factory automation application.

In addition, to make the design process more convenient, Tebis CAD / CAM provides a library of standard geometry for a number of drill holes, components, machine parts, standard shelving, etc.

The NC programmers at APH3G first used parameters in the process library to analyze machines, controls, tools and clamping devices as individual digital objects. Since then, the Tebis software builds a hypothetical production environment with objective factors that can affect product quality. Next, the NC programmer uses NZ templates containing proven production sequences as well as suitable clamping tools, machines, and equipment from the virtually hosted process libraries. This allows Tebis NC programs to optimally adapt to the production environment and pre-detect and avoid collisions during actual production.

(To be continued)

Productivity and Quality Office