Shinmeido products ensure quality according to ISO 9001: 2015

Established in 2007 with main production areas being industrial molds and plastic products, in 2010, Shinmeido Industry Joint Stock Company applied ISO 9001: 2008 quality management system. In order to improve product competitiveness and meet integration requirements, in 2017, with the support of Program 712, the company successfully transformed the ISO 9001: 2015 quality management system.

As one of 36 enterprises selected to participate in the Program “Supporting the conversion of quality management system according to ISO 9001: 2008 to the new version of ISO 9001: 2015 for industrial enterprises” of the Ministry of Industry and Trade implemented by Vietnam Productivity Institute, 24Shinmeido Industry Joint Stock Company is determined to implement and apply ISO 9001: 2015 quality management system synchronously and effectively, aiming to build trust with customers, improve High corporate image.

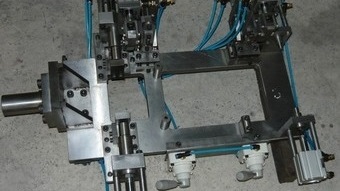

The project was implemented and applied in the management of standard and non-standard steel structure processing projects for transportation, civil and industrial construction with the advice and support of Institute experts. Vietnam productivity. The objective of building and perfecting the quality management system in accordance with ISO 9001: 2015 in order to improve the capacity of the company and the specialized departments, factories and factories to meet the increasing requirements of customers as well as development orientation in the coming time of the Board of Directors. Scope of construction and application of ISO 9001: 2015 at the company’s headquarters in Phu II Area (Dong Anh, Hanoi) until the certification of the fields: Manufacturing and trading of molds and products plastic.

Mr. Nguyen Trong Thai – Director of the company – said: Within the project, experts from the Vietnam Productivity Institute have instructed the company to strengthen the Project Steering Committee for implementation of ISO 9001. The company also appointed representative leadership on the quality required by the standards, assess the status of the existing management system compared with the requirements of ISO 9001: 2015 to find out the incomplete points that need to be added or Revision. In addition, three training courses were conducted with the following contents: Training changes and guidelines for converting the quality management system to ISO 9001: 2015 version; update document system according to new version ISO 9001: 2015 and internal evaluation. The project has helped businesses perfect the system of management documents, documents that have been developed and issued for application in enterprises such as: Quality policy, quality objectives, quality manual and 10 processes (production, document control, etc). 100% of the products produced are subject to quality control, especially sample products, through the establishment of strict control steps into popularized and strictly implemented procedures; improve efficiency in risk management.

Along with perfecting the quality management system according to ISO 9001: 2015, Shinmeido has actively applied JIS management standards and productivity improvement tools according to 5S to management and production. This has helped the company improve productivity and product quality; Join the global supply chain.

Productivity and Quality Office