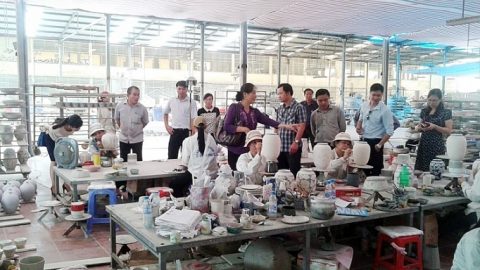

Quang Vinh ceramics production workshop

Quang Vinh Fine Arts and Pottery Co., Ltd, formerly known as My Hanh fine arts ceramics export group, was established in 1989. Originally from Bat Trang ancient pottery village, operating in the form of a family business including a complex of 6 members, so far the company has 2 production facilities in Bat Trang and manufacturing plants in Mao Khe Ward and Quang Ninh with a total workforce of nearly 400 labors. Nearly 95% of the Company’s ceramic products are exported to foreign markets: Japan, Australia, USA, Germany, England, France, Denmark, Sweden, Netherlands, Spain, Israe, etc, export turnover from 2012 to now always average 2 million USD / year.

In order to create a new competitive product, improve production productivity, product quality and save costs, reduce product costs, in early 2019, Company has invested a 12-ton twin press machine, a multi-head CNC engraving machine and semi-flexible presses, reaching a production capacity of about 700,000 products / year at a cost of more than VND 600 million.

Along with the equipment, investing in new machinery, combining the technology of mixing thin porcelain enamel bone by the research company and semi-automatic high pressure pouring technology help the product create beautiful, durable and accurate high, outstanding in quality and diverse in categories. Thanks to the high accuracy, the ratio of defective products, reduced defects and style of standard products, improve the aesthetics. Investing in CNC engraving machines in decorative products to create more diverse products, increasing labor productivity and almost no defective products.

According to Ms. Ha Thi Vinh – General Director of Quang Vinh Ceramic Company, with modern technology, it will help lower the cost of products by over 30%, thereby improving the competitiveness in the market, and increasing the opportunity to expand the market.

Especially, completing the investment project of advanced production lines and equipment in producing high-class ceramics, Company has recovered excess heat in the kiln to dry carpentry products, reducing 30% of gas costs. Quang Vinh Ceramic is the first business in the North to bring Taiwan high-tech gas-fired furnace to replace coalAdvanced technology helps the Company reduce the number of defective products, increase product quality and productivity, and lower product costs, protect the environment. Thanks to these advantages, Quang Vinh Ceramic enhances the image, quality and has the opportunity to lower the selling price of products, boost competitiveness and expand markets and production.

Productivity and Quality Office