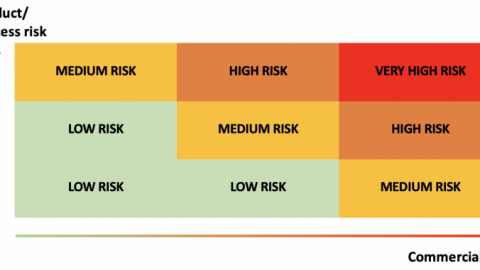

Every buyer knows that some orders are more risky than others, and the risk affects many of the decisions they make. This is why quality planning and sorting orders based on the level of risk are important for importers.

Look at the overall picture:

Sorting orders is a smart way to visualize the situation.

Now, what to do with orders falling in the red or orange areas? They need special handling. The group of buyers should have more than what they can hold “in their hands” (Eyes see the headphones. Eg give customers the product to try).

In real terms, what can you do?

I don’t know your exact situation, but here are the two most typical examples:

Example 1: Quality planning for orders in the red area

Qualify the factory before giving them an order – auditing them, making sure they perform the basics of process control and they have a solid quality system.

Be clearer about your quality standards, if possible with a detailed checklist and a perfect template, but also with boundary patterns. Train their people on your standards.

There was a backup factory ready to run to the ground so things didn’t go well.

If the process is somewhat different (custom), don’t skip the test run. Another approach is to cut the order into two small orders (which will be processed at different times, instead of in large batches).

Top the list of issues raised and promote the improvement of the most serious problems.

There is someone on the site to test the ingredients, then to check the article first, and during production.

Example 2: Quality planning for orders in the green area

Qualified factories ensure they have the basics of a quality system.

Give them a clear quality standard

Perform a final random check, or (if the supplier has a good track record), ask them to check for themselves.

Productivity and Quality Office