ACG Group is an organization specializing in providing technology solutions and services for the pharmaceutical industry. Recently, ACG has launched a number of new packaging equipment with many outstanding features at the same line.

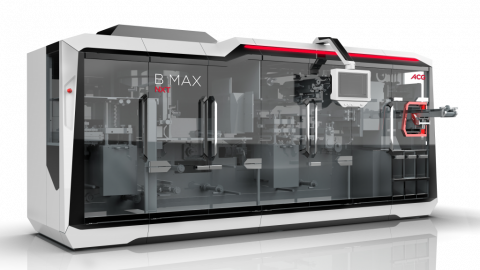

These packaging equipment include: Protab 300 NXT, Protab 700 NXT, BMax NXT, KartonX NXT and Verishield CS18 NXT, belonging to the NXT product line developed by ACG’s Engineering and Testing department. NXT has the ability to provide flexible choices to users about automation processes. Specifically, in the stage of tablet pressing (pills), NXT can force to shape the tablet according to any design and combine with other equipment to stamping into blisters and bagging automatically.

Not only that, the new NXT device line also has some features that are superior to the old products in the same line, ACG calls these features USER. Speaking of USER, it is an acronym for Super Console (UltraHMI), Streamlined Design (StealthDesign), Augmented Reality (ExploreAR) and Internet of Things (RevealIOT).

- About UltraHMI: This operating interface is suitable for promoting the continuous execution of automated processes. Thanks to the ability to control sophisticated machinery with high accuracy, the barrier between the operator and the device is almost zero. Especially, UltraHMI also provides the ability to expand the data collection process thanks to the Internet of Things (IoT) applications.

- About StealhDesign: With its “neat, smooth design”, the new appearance of the device demonstrates ACG’s commitment to flexibility, maneuverability and the ability to create maximum output with removable space. transfer to a minimum.

- ExploreAR: By harnessing the potential of augmented reality technology, NXT helps businesses reduce downtime, identify and resolve maintenance-related issues faster and help optimize process flow. manufacturing. Outstanding features of this feature include: Real-time monitoring, remote diagnosis and proactive service support, preventive maintenance and operator training in the simulation model.

- RevealiOT: ACG’s Internet of Things platform provides inter-computer connectivity and supports intelligent manufacturing processes through control panels. This also helps users to collect data and evaluate KPI indicators that are difficult to measure by conventional data collection methods. Through data analysis, users can perform predictive maintenance to reduce manufacturing process errors, improve product quality, and improve overall equipment performance (OEE).

With more than 50 years of experience in the pharmaceutical industry and 4500 partners in more than 100 countries, ACG has affirmed its position in the international arena and is constantly improving its products and technologies to gained more achievements.

Productivity and Quality Office