Founded in the 1970s by the research team of Dr. John Swanson, ANSYS is now a popular software based on finite element methods to solve problems and simulations in many fields such as mechanics structure, heat transfer, fluid mechanics, etc thereby reducing time in product design. As is well known, all technical problems can be described using mathematical equations, especially the most common form of differential equations with boundary conditions.

ANSYS (NASDAQ: ANSS) announced that DENSO, a worldwide automotive supplier, has selected ANSYS® FEM software to standardize and expedite product development globally, enabling the company to cut costs and boost competitiveness in a tough marketplace. DENSO will use the CAE software to increase efficiency and enhance product quality across its portfolio, which includes automotive powertrains, advanced electronics, thermal systems, refrigerators and air conditioners.

DENSO underwent a rigorous benchmarking process in choosing ANSYS, then selected the solution because of its advanced analytical abilities for structural linear, nonlinear and dynamics analysis; its ability to model with elements, its library of material models and equation solvers; and its scalability in efficiently modeling a range of engineering problems and scenarios. DENSO found the support provided by long-term ANSYS channel partner Cybernet Systems especially valuable.

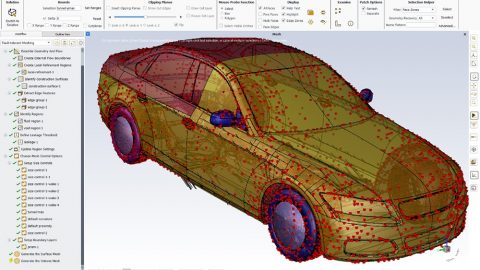

Currently, ANSYS is the most popular software that uses the FEM method to calculate. In the world, the application of ANSYS to research and product design has been applied for a long time, but in Vietnam, this has only been applied by scientists and engineers since the early 2000s. It can be said that this application helps a lot of time in the design and testing of products. Some examples can be mentioned in specific fields such as:

Source: ANSYS