For manufacturers, the application of software to support the management process is extremely important, especially when the Industrial Revolution 4.0 is gradually taking shape. Most 4.0 technology software aims to provide data-driven analysis and evaluation automatically and help managers make the right decision.

Manufacturing Analytics – Collecting data, in context, in real-time provides you, the manufacturer, the opportunity to evaluate that data to make forward-thinking decisions about the productivity and efficiency of your plant. A bonus? Manufacturing analytics can work with other software, such as a CMMS, ERP or QMS system, to integrate for efficiency.

Simply put, data collection and evaluation become a reality with smart technology and eliminates the need to manually track that data via pen and paper, a huge time-saver.

There’s no question – there are a lot of manufacturing software options out there, but how do you know what is best for you and your company in order to reach the coveted status of a “Smart Factory”?

Do Manufacturers Need an ERP System?

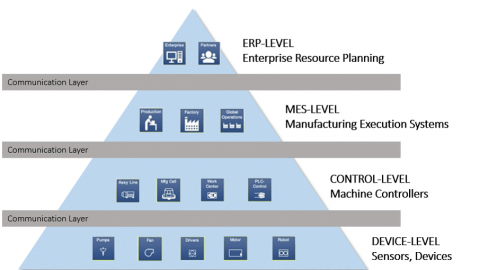

The short answer is, yes. As a company grows, an ERP is necessary to stay organized and continue on that path of growth. However, that does not mean an ERP system can solve all problems. Essentially, the data the system will provide is high-level, meaning you can make decisions for the future based on the events of the past, but it fails to collect data for one very important action – those events that occur in real-time. You will not be able to analyze how things are running right now, what to do to make those processes more efficient, or evaluate real-time trends.

What’s the Difference Between ERP and MRP?

As you begin researching smart software solutions, it is likely that you’ll come across the terms MRP and ERP. Most definitions don’t provide much differentiation between the two, but there are a few key differences that set the terms apart.

An ERP is a connected, integrated software that looks at the organizational processes of the plant as a whole while an MRP can be a standalone software that allows you to track materials to ensure the highest rate of production. Used together, the two can be very efficient

With an ERP system, it will likely be used across all facets of a company – from the plant floor to human resources to even accounting. MRP software, on the other hand, is strictly limited to the factory floor.

Cost is one of the biggest differentiating factors when discussing the two manufacturing software. An ERP is often an expense, large-scale solution while an MRP is inexpensive compared to the former due to our next point, scale.

An MRP is a smaller scale solution as one can guess due to the scope of the users. It is used only on the plant floor while an ERP system is used throughout the organization.

Source: Sensrtrx