Levi uses a laser to sharpen jeans

Levi Strauss, the world famous jeans company, has just brought a new digital technology to handle jeans. They used lasers to create designs on cow’s fabric, a process that had previously been complicated.

Called the FLX Project, which stands for Future-Led Execution – The Future’s LED Led Treatment, this technique will completely eliminate the pants of handling pants with toxic chemicals and reduce the steps of handling pants Tired craftsmanship before. Before FLX Project had born, a pair of jeans took 18 to 24 steps to complete, now only 3 steps are left.

Levi intends to expand this project to all facilities of the denim fabric supply chain.

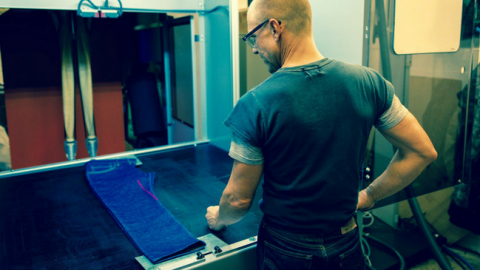

“The first step in this new process is to take a picture of the jeans, then we take that picture and illustrate it so the laser system can understand it. Previously, the traditional way required 8, 10 or 12 minutes to make it, now the laser system can do it in 90 seconds, ” said Bart Sights, vice president of technical innovation, The creative department is called Eureka Laboratories. These lasers are infrared rays etched onto the denim of an existing design, creating the common abrasive and tearing effects on pants.

Levi said that over the past 30 years, the clothing industry has used manual methods along with a chemical treatment of pants to create a grinding design on the pants. This project is a step forward of the company in response to the statement “do not use toxic chemicals by 2020”. The laser system will replace chemicals for handling pants, reducing toxic to workers and reducing pollution for the environment.

Another advancement in this project is the new imaging device, which can create complete pants on a computer. It will allow designers to edit colors, change the design of the tear or tear. In the past, sample pants were often real products, still created by conventional methods of making pants: using chemicals, handling pants by hand to create a test product.

The company claims that the new digital tool will reduce pants production time by half, from months to weeks or even days. Those digital pants will be integrated into the laser system, both creating a prototype and a mass production line.

It is expected that by 2020, this digital technology platform will be completed and widely applied on Levi’s lines.

However, Levi is not the only company using high technology to create products.