Not only has a flexible design, Hoffman’s Garant Xtric also has a lot of outstanding features.

With double spring construction and linear clamping, the clamping force of the device can be up to 25 kN. The special tooth design of Garant Xtric helps to keep and clamp the products, even in strong shock environments. If a clamping force of 25 kN is applied directly to the part, the device is also suitable for clamping unfinished parts. If using the jaw clamp with the form of Garant teeth, the pre-stamping stage can even be removed.

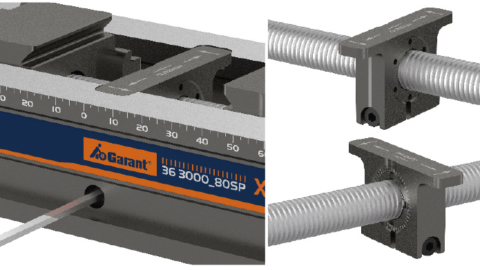

To clamp larger workpieces using multiple centering holes, the center can be precisely adjusted – micrometre precision. And, if necessary, can be moved up to 0.5 mm on each side (a total of one mm). To do this, simply release the screw on the side, reset the center using the screw pins, and then re-screw the screws on the side.

For customers who have experienced the “Lang” system, they will understand that Hoffman always provides a variety of upper jaw suitable for the “Lang system” tooth type. Users are allowed to select different settings: The product can be used for point clamping through direct adjustment on a “Lang” system or with a converter on all “Zero-point” clamping systems.

Another prominent feature of Garant Xtric is the rotation function: The gripper automatically adapts and changes to the surface of the workpiece, and can also be used for finishing parts (parts ensure the clamping is done carefully to avoid scratching the surface of the product).

If you are a manufacturer looking for a flexible car with high compatibility with many different machines, Hoffman’s Garant Xtric is the solution. However, if your requirement is to improve the speed and intensity of the production process, 1st Machine Tool’s Qwik-Lok is the more suitable choice.

Unlike Garant Xtric, Qwik-Lok’s design does not pay much attention to open joints and limit rotation. Instead, it provides quick fastening while also increasing stability when clamping multiple pairs of parts at the same time.

By rotating a single handle, the two Qwik-Loks can move simultaneously towards a fixed center vise to grip parts, which also eliminates opposing forces and creates a reliable reference point for performing machining. Overall, the Qwik-Lok equipment has many outstanding advantages to help manufacturers speed up their processes.

(To be continued)

Productivity and Quality Office