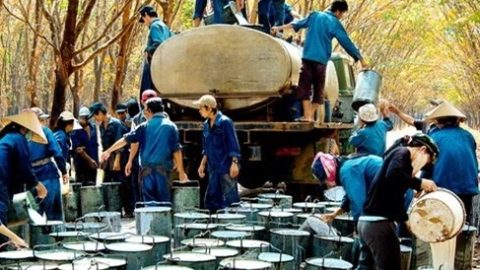

Workers of Tay Ninh Rubber Joint Stock Company during latex harvesting time

Since the program of improving productivity and product quality for Vietnamese enterprises has been maintained, many businesses have applied advanced quality management systems, and energy improvement tools until now. productivity and modernity in the production process, thereby bringing practical effects to businesses in order to improve productivity and quality of products and goods.

Mr. Nguyen Van Hanh – Deputy Director of Tay Ninh Rubber Company, said that the company is currently implementing 3 quality management systems according to ISO 9001: 2015, ISO 14001: 2015, ISO / IEC 17025: 2017 at the same time applying Kaizen quality productivity tools. The company has developed and applied a Kaizen improvement program from 2015 to present that has brought practical benefits.

From 2015 up to now, the Company has had 63 initiatives. Innovative initiatives help the Company not only save raw materials, fuel, chemicals, and electricity, but also contribute to reducing labor force, protecting the environment, reducing costs, increasing labor productivity and improving labor productivity, thanks to which the company can save up to 7.2 billion.

Ms. Ho Thi Bich Loan – Head of Quality Control Department (Tan Bien Rubber Company) shared that the company has researched, built and successfully put into application management systems, productivity improvement tools. product quality according to ISO 9001: 2015, ISO 14001: 2015. The company minimizes waste in production, improves competitiveness with other businesses in the same industry. At the same time, everyone in the Company is encouraged to participate in the process of improving productivity and quality. Thanks to that, product quality control is better implemented.

Since applying the advanced management system, productivity and quality improvement tools, the product failure rate is no longer available; Customer complaints are also significantly reduced. Currently, the Company has improved the process of drying latex products with gas, this innovative solution has both improved product quality and ensured environmental hygiene. Previously, rubber latex products were dried by oil, the product quality was low, not good for the environment.

At the same time, the Company also improves the production line by applying additional testing of latex viscosity, screening of input materials to process suitable for each type of product. Applying the drying of 12 knives, cutting one machine for the coarse chopping process, helping the raw materials to be minced more finely, the pus is even to create a more quality product.

After a period of implementing the management system, productivity improvement tools, and the quality of the Company’s brand reputation have been significantly increased. The production process is strictly controlled; minimizing risks and errors, thereby reducing production costs, increasing labor productivity and improving product value.

In 2020, the Company will continue to implement and maintain the Kaizen quality productivity improvement tool, and at the same time departments within the Company are also actively registering improvement topics for their divisions. In addition, the Company also aims to apply the sustainable development program according to FSC standards, the energy audit program, the tools to improve the productivity and quality of CLEAN lean production, build a balanced card system. Balanced scorecard and applied Industrial Revolution 4.0, specifically the application of Blockchain technology in the agricultural industry such as product quality assurance (QA), traceability, real-time management, supply chain application, etc.

Productivity and Quality Office