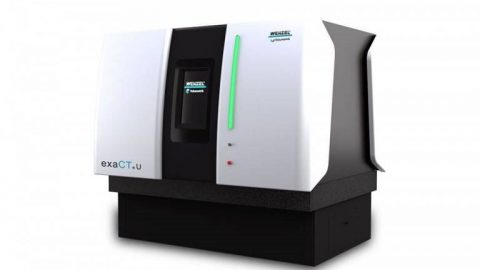

The machine interface supports data collection and analysis (Source: Equipment–news)

“Industry 4.0” will no longer be just a slogan if manufacturers successfully apply 4.0 technology to benefit consumers, according to Wenzel.

Many different projects can be initiated from the same platform – the Wenzel software. This protocol is able to meet the high demands of the business and can show measurable benefits. For example, in 3D printing, Wenzei 4.0 helps businesses have more accurate access to customer requirements, especially when they face problems with materials and details.

Increase throughput and improve flexibility

Wenzel software can program and support managers to update order information directly without going through a lot of paperwork. Besides, Wenzel 4.0 is also quite user friendly, helping to improve flexibility and increase throughput. This helps businesses score in customer service, fast and efficient access.

Collect and analyze data

Enterprises easily collect, analyze and present data related to the machine’s application via the IMI interface. This system can collect and process information including ambient temperature, humidity, machine performance or any other information related to the machine or its components. From there, the sensors are also integrated and information from the controller is also used. Alerts, status reports or measurement programs are also integrated through the application, processed and evaluated by each type of machine and in different cases.

Access information anywhere

Manufacturers can opt for Miguard wireless networks if they need to set up and connect machines in multiple areas, this solution will meet their needs globally. If they need it, the data is also transferred to safe areas for quality assurance. However, Wenzei’s technicians will sign contracts with them; The contract includes 2 types: Maintenance contracts and predictive maintenance contracts.

The Mi-Wpanel system allows managers to receive interactive notifications and review status of machines quickly. What’s more, they can access data anytime and anywhere with just a mobile device such as a tablet or smartphone. It is also more convenient to monitor the work in the measuring room or other machines.

In general, data collection is an important step in the improvement cycle and improve the measurement performance of working machines. New software solutions will certainly bring high performance in projects.

Productivity and Quality Office