As mentioned in the previous section, QFD’s goal is to bring customers products that are not only high quality but also suitable for their needs and tastes. QFD helps to effectively communicate customer needs to a wide range of activities across the organization from design, production, quality control to marketing and sales. In addition to significantly improving the competitiveness of the organization, QFD also offers many additional benefits such as:

Customer-focused sustainability: The QFD approach focuses on the real needs and needs of the customer, not what the company wants customers to believe they need them. Voice of the Customer (VOC) is transformed into specifications in product design, which are then realized at the system level and feasibility at the machine level. Finally, the design specifications are controlled throughout the manufacturing and assembly process to ensure that the customer needs are met. All of these contribute to giving customers a full confidence that they are being heard and respected. This is one of the indispensable foundations of a sustainable business.

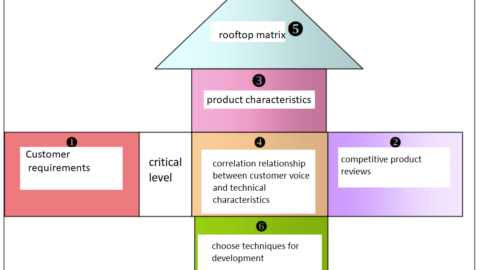

Competitor analysis via VOC: QFD’s “Quality Home” tool allows you to directly compare your design or product to your competition through VOC feedback. This quick analysis can be beneficial in making decisions or designing to stay ahead of the market trend.

Shorter development times and lower costs: QFD reduces the rate of design change requests when the production process begins by focusing on product features and improvements based on the requirements of customer. This reduces wasted time and other resources on developing non-value added features or functions.

Build a legacy framework and documentation: QFD provides a structured framework and tools for documenting the decisions made and lessons learned during product development. This knowledge base can serve as a legacy profile that can be used to support future projects.

Nowadays, Quality Function Deployment (QFD) process is being widely applied to a wide range of products and services, from consumer service to military or high-tech fields. This technique is also used to design workpieces and formulate competitive markering strategies. QFD is considered the key to Desing for Six Sigma (DFSS). It is also included in the ISO 9000: 2000 standard that focuses on satisfying customer needs.

Productivity and Quality Office