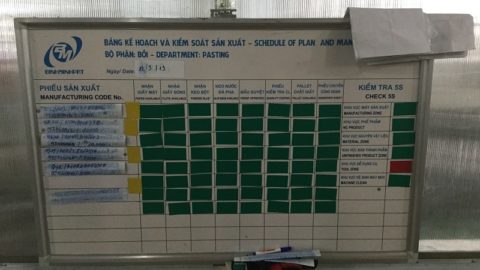

Production control panel at Boi stage of Binh Minh PAT Co., Ltd

Promoting the application of models and tools to improve productivity and quality to improve the competitiveness and operational efficiency of enterprises is one of the key contents of the National Program “Improving productivity and quality quantity of products and goods of Vietnamese enterprises to 2020”. Within the framework of the national productivity and quality program, the first 06 pilot models applied Mizusumashi and Kamishibai with 10 successful case studies.

The increasing demand of businesses requires organizations and consultants to continuously update new advanced management content and methods to help businesses increase productivity and reduce costs.

Mizusumashi (Production Coordinator) and Kamishibai (Production Control Panel) are two Japanese-style management tools belonging to the tools of the Toyota production system, suitable for small businesses. and medium, focus on managing image and human factor to help reduce waste, improve labor productivity. This will therefore assist very well in the deployment of other quality productivity tools. Kamishibai and Mizusumashi have been researched and developed by organizations and individuals around the world many years ago.

Over a long period of practical application in many businesses in many countries, it has been increasingly improved to help businesses reduce waste and improve productivity. Although, Kamishibai and Mizusumashi have been strongly and effectively deployed by countries around the world to improve productivity, in Vietnam, there is no official information about the application of these two tools in Vietnam enterprises.

Within the framework of the national productivity and quality program, the first 06 pilot models applied Mizusumashi and Kamishibai with 10 successful case studies. Thereby, it helps businesses improve productivity, reduce costs and create a friendly working environment, ensure occupational safety for employees with the effectiveness measured specifically by data and clear illustrations. . Enterprises participating in the task appreciate implementation results and have plans to replicate the model applied in their own businesses as recommended by the expert group. In addition to the organizational efficiency such as helping to reduce slow orders, reduce bottlenecks, improve the use of images to help disseminate production and business management related content at the enterprise, etc. The mission also brings practical economic benefits to the businesses selected to participate in this pilot model. With initial investment costs for 10 successful case studies of 32,500,000 VND, the six pilot enterprises have saved more than 300,000,000 VND / year.

With the number of enterprises selected to participate in the mission (06 enterprises), although it is a very modest number compared to the number of small and medium enterprises in the country, the results achieved have important starting meaning, contribute to gradually improving the capacity of Vietnamese businesses and a contingent of quality productivity and quality consultants. There is a significant change in the perception of existing types of waste in participating businesses, problems that previously were daily activities were obvious problems. After implementing the application process, depending on the specifics of the application tool is Mizusumashi or Kamishibai, businesses will identify the existing problems and identify the types of waste, so that there are appropriate solutions. in order to reduce costs, improve productivity, reduce environmental impacts, and contribute to improving corporate image.

The mission has also contributed to creating a premise for the movement to improve productivity and quality in enterprises, associated with the group’s activities of continuous improvement and improving the efficiency of production and business activities. The level of success of each model has different points of scale and scope, but all have a new approach to quality productivity in a complete and intuitive way. Over the course of the mission, in addition to its economic values, it also increases the awareness, expertise and skills of an enterprise’s human resources staff on general and quality productivity improvement tools. tools Mizusumashi and Kamishibai in particular.

Productivity and Quality Office