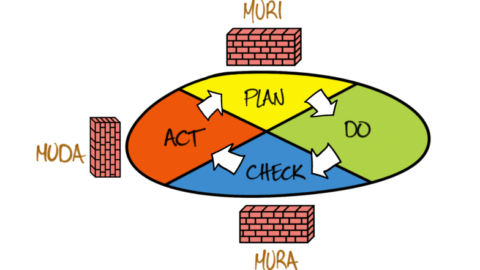

When you first start adopting the Gemba Walk tool, being mindful of muda, mura, and muri can give you a solid foundation for looking at your organization’s activities. Here are some questions to help you better access the causes of waste with the 3M method:

About Muda

Muda often comes across different scenarios: Overproduction occurs when items are manufactured before they are ordered; Processing occurs when more work is put into a product or service than needed; Inventory is important, but storing too much or too little material and finished goods increases costs and takes up space; Transport is the movement of products and supplies from one area to another; Motion is the physical movement of a person or machine needed to complete a job; Waiting is when work or project is delayed or sluggish because the machinery has not finished the required production, the product has not arrived yet or some other part is holding the rest of the project; Defects occur when errors and repetitions are generated from your processes.

You need to search and locate:

About Mura

This is a common situation when companies accelerate production to meet customer requirements. This forced the sales department to try to fill orders and put a heavy burden on the shippers who quickly shipped products before the end of the month. This leads to consequences: The product quality is not guaranteed; The customer receives an incompatible product or service; Manufacturing competes to fulfill large orders and becomes idle when orders drop. Even more is involved with Mura’s creation of Muri (overload), which in turn undermines Muda’s efforts to get rid of seven wastes.

You need to find and locate:

About Muri

As explained in part 1, Muri overloads both humans and machines, leading to a decrease in the overall system’s performance for a later time.

You need to search and locate:

Other causes

For example, when workers lack the right tools for the job, the tasks become more difficult and take longer, and operations are more prone to errors. For example, machining sheet metal with hammers and iron drills will damage the panel you are working with – tripling the time it takes to complete the task and causing the batch to be remanufactured.

You need to search and locate:

In general, muda, mura and muri are three distinct types of waste, but also closely related. Through thoroughly addressing one waste, the settlement of other wastes also becomes more favorable.

Source: Kaizen News