In order to avoid errors in manufacturing processes, traditionally two types of checks have been used:

Moderation is also known as final or standard inspection. This method is used to assess the quality of output based on random sampling plans. This does not really improve process efficiency and should only be used in the short term as it only detects defects and does not contribute to limiting them. The two risks associated with sampling inspection are the risk of facing the customer (rejected because of a high failure rate) and the brand risk (accepting a defective product delivered to the consumer).

Information check is also known as in-process inspection. This method evaluates the process by examining the output and using the information obtained to make adjustments in the next process. This is relatively less risky and reduces the probability of error in the interval between sampling intervals.

However, the testing method that Shingo recommends is a source inspection, which is a prior assessment of whether there are any factors that affect product quality. This helps to minimize defects that can occur right from the beginning of the process. Priority for source inspection is also based on an important rule known as Rule 1-10-100, meaning that when a product or service moves through the production system, remedial costs are often 10 times higher after each step.

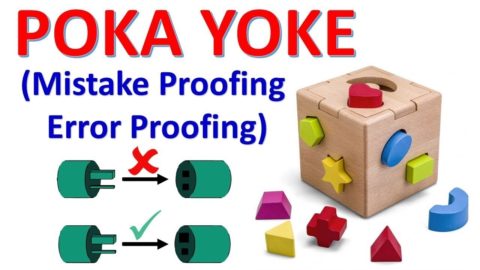

No matter how much prepared and tested the operator or machine is, it is still possible to make a mistake. So how do we achieve the disability-free goal? The answer is Poka-Yoke – a process that guarantees failure does not constitute a defective product.

The Poka-Yoke system consists of three main methods. Each method has its own advantages and brings practical benefits to businesses. Specifically:

Movement sequence: This method uses sensors to determine if a movement or step in a process has occurred. If the operation does not happen or occurs out of sequence, the sensor will signal a timer or other device to stop the machine and alert the operator. This eliminates the risk of creating defective products while keeping the line running properly.

Contact method: No need to be high-tech! Physical, visual alarms are sometimes the best approach. They can be as simple as pins or guide blocks that do not allow parts to be misplaced prior to handling. Take advantage of parts designed with an uneven shape! A workpiece with holes, protrusions or an uneven end is the perfect candidate for jigs. This method immediately signals the operator that the part is not in position.

Counting method: Used when a number of fixed operations are used in a process or when a product has several permanent parts attached to it. A sensor counts the number of times a part is used or a process is complete and releases the part only when the right number is reached. Another approach is to pre-count the number of parts or components needed to complete an activity. If operators find leftover parts using this method, they will know what was left out of the process.

Productivity and Quality Office