Currently, Vietnamese enterprises are mainly small and medium enterprises often do not have the capacity and resources to implement the synchronous deployment and application of innovative tools on an enterprise-wide scale, but should choose to apply each part, using simple techniques and without cost or with low cost.

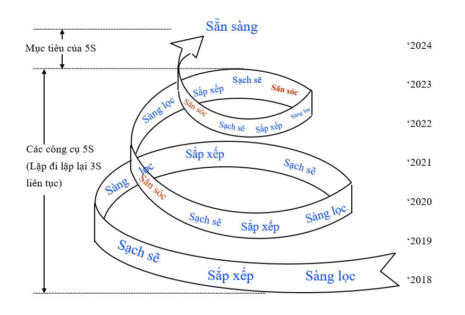

Usually, the application of any improvement tool will encounter a number of objective or subjective barriers from within the company, which significantly affect the progress of the improvement process implementation. For example in the implementation of 5S, in order to be able to maintain and bring long-term effectiveness, the implementation of the simplest tools like 5S also needs to maintain compliance for many years.

According to the above diagram, during the 5S implementation, repeat in a spiral circle, however, each repetition is an upgrade of good practice 5S activities. Below are instructions for recording 5S iterations and upgrades:

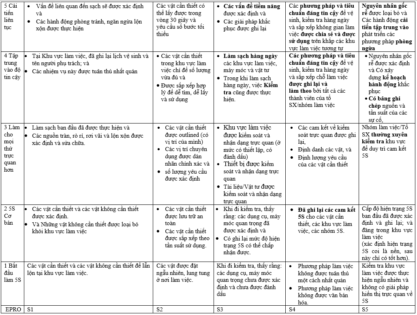

5S level 1: Start doing 5S

S1: Necessary objects and unnecessary objects to mix up in the work area.

S2: Randomly placed, random objects in the workplace.

S3: When we went to check, we found that: important tools and machines have not been identified and have not been marked

S4: Work method is not consistently followed; The working method is not documented.

S5: Work zone testing is done at random and there is no solution for 5S visualization

5S level 2: Basic 5S

S1: Necessary objects and unnecessary objects are identified; Unnecessary items are removed from the work area;

S2: Necessary items are stored securely; Necessary items are sorted according to frequency of use.

S3: When inspected, found that: important tools and machines have been identified and; There is a record of acceptable level of 5S status.

S4: Recorded 5S commitments for essentials, work areas, 5S teams.

S5: Initial 5S status level was identified and recorded; and post in the work area (defining the current status 5S as the background, the later only gets better).

5S level 3: Make things more intuitive

S1: Initial cleaning was performed and sources of spills, leaks, spills and mess identified and repaired.

S2: The requisite was outlined (had his position); The dedicated positions are precisely labeled and the required number is identified.

S3: Work area controlled and visually identified (at set level, marked); Equipment is controlled and identified visually; Documents / Materials are visually controlled and identified

S4: Commitments for documented visual controls; Identification of objects, and Quantification of required items;

S5: Working group / Production team regularly checks the area to maintain the 5S commitment.

5S level 4: Focus on reliability

S1: In the Work Area, cleaning schedule and name of person in charge have been recorded; and these tasks are consistently followed;

S2: Items needed in the work area are of sufficient quantity and are properly arranged for ease of access, access and use;

S3: Daily cleaning of work areas, machinery and supplies while daily cleaning, Checks are also performed.

S4: Reliable methods and standards for cleaning, daily checks and worksite arrangements documented and followed by all members of the production team / workgroup;

S5: Root causes are identified and a corrective action plan has been developed; There is a log of the source and frequency of incidents,

5S level 5: Continuous improvement

S1: The issue related to cleanliness is identified and actions to prevent and prevent clutter are taken

S2: Essential items can be retrieved within 30 seconds and a minimum number of steps is required;

S3: Potential problems identified and corrective actions documented

S4: Reliable methods and standards for cleaning, daily inspection, and workspace arrangements are shared and used across similar work areas;

S5: Root causes are removed and improvement actions focus on development of preventive methods

Productivity and Quality Office