What are the benefits of the digital twins?

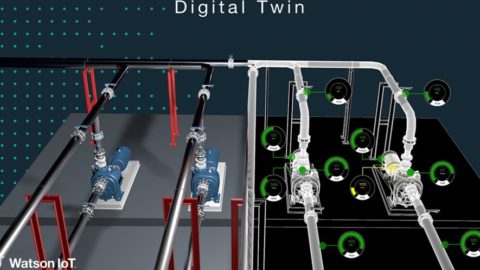

In addition to performance, safety, and maintenance conditions, there are many other benefits associated with using the digital twins for business. First, they can dramatically improve the efficiency of existing processes, and the products and services that come with them are always at the forefront of capturing new opportunities. They can also cut production costs a lot. The digital twin also pushes traditional manufacturing to new heights through intelligent connections between products.

Early digital twins often focus on opportunities to improve the performance of their products while minimizing the costs and risks associated with new product launches. Furthermore, the digital twins can speed product realization by cutting down or eliminating factors that take time to actual product construction.

This leads to increased profits because manufacturing can only grow rapidly when factors that slow down production are discovered and eliminated. After all, when manufacturers use digital twins to simulate the value of their products before they manufacture it, they get benefits that were not previously expected.

Using digital twins for the supply chain

Supply chain managers need to approach and learn about the digital twins soon. From a global perspective, their proprietary sourcing and sourcing perspectives, as well as their honed troubleshooting skills will play a key role in defining and refining the values and project variables.

When the role of the digital twins is promoted, manufacturers can create different values for each customer and for each product depending on the functionality and value competing. Manipulating huge chunks of data is costly and the process of building for the digital twins is also time consuming. However, the learning and learning phase is likely to become the most important stage in the construction process for the whole system, and it will also open up many great benefits for managers and stakeholders.

Productivity and Quality Office