Robots replace people for hard and difficult jobs

The demand to improve Productivity and product Quality is increasingly requiring widespread application of production automation facilities. A trend of creating highly flexible automated equipment lines is developing. These devices are gradually replacing the ‘hard’ automatic machines that only meet a certain task while the market always requires changing items in terms of types, sizes and features..v..v . Therefore, there is a growing demand for robot applications to create flexible automated production systems.

The concept of industrial robots was born in 1954 when a robot was capable of lifting and laying down patented objects in the United States.

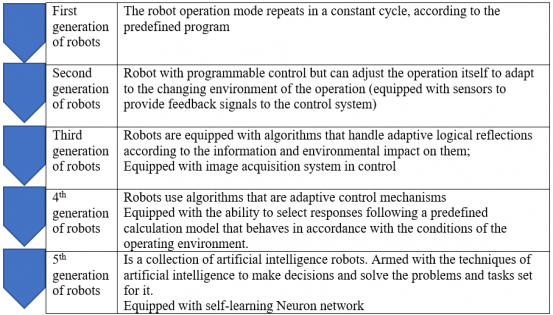

Fingure. Classification of 5 generations of robots

In 1975, Unimation began to profit from the first robot product.

The first industrial robot was put into use in 1961, at a General Motors automobile plant in Trenton, New Jersey USA.

In 1967, Japan imported the first industrial robot from AMF. By 1990, more than 40 Japanese companies, including giants such as Hatachi and Mitsubisi, had introduced to the international market many famous robots.

Since the 1980s, especially in the 1990s, due to the widespread adoption of advanced microprocessor technology and information technology, the number of industrial robots has increased, the cost has been clearly reduced, and the features There have been many great strides. As a result, industrial robots have played an important role in modern production lines.

For industrial robots, linking multiple robots to create the ability to work with people has been put to practical use. For example, CR-35iA, a collaborative robot manufactured by FANUC Corp. in 2015 and Coro Co-robot by Life Robotics Inc. Produced in 2015, can work with people without safety barriers. In addition, NEXTAGE, produced by Kawada Robotics Corp. In 2011, there was a structure that mimicked the human torso and the robot was able to perform tasks that had previously been performed by workers.

Industrial robots are understood to be flexible automated devices that mimic the industrial labor functions of humans. Talking about flexible automation equipment is about the ability to manipulate with many degrees of freedom, servo control and programmable. Also referring to the imitation of the industrial labor functions of man means the limitation of simple manual labor to artificial intelligence, depending on the type of labor required. to that function or not. It also talks about the need to imitate like humans.

Productivity and Quality Office