Northwestern's HARP technology

The component printing industry, also known as 3D printing, has been in a technological breakthrough for the past decade. From point-to-point and batch-production processes to participating in large-scale production line systems with a variety of different products.

As technology is becoming more and more popular, and materials are constantly improving over time, printers gradually became cheaper and more commercialized, thereby printing speed and size. Ruler details also have big changes.

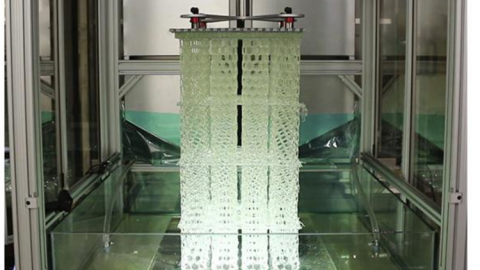

HARP (for High-area rapid printing) is one of the latest 3D printing technologies from Northwestern University, where researchers have developed a 3D printing tool of the future capable of printing clickable details. the size of an adult in a few hours.

Northwestern University says that this new technology sets a new record for producing custom parts. The prototype version is a 13-foot-tall printer with a printable table width of up to 2.5 square-feet (1.9 square meters) that can print 0.5m-sized objects in just 1 hour, something that houses Research says to take notes while 3D printing. This giant printer can print a large size object or many small objects at the same time.

“Conceptually, 3D printing is really powerful, but it is limited in practice,” said ChadA.Mirkin of Northwestern School, the manager of this development project. “If we can print fast without restrictions on materials and dimensions, we can revolutionize the manufacturing industry. HARP was created to do that.”

Using the latest sensor system – a 3D printing model that converts liquid plastic into hard objects, HARP prints objects vertically and uses ultraviolet light to change the structure that makes liquid plastics become Solids. Using this technology allows HARP to print very solid details such as plastics or even ceramics.

Northwestern researchers say the results when printing the parts are fundamentally solid, in stark contrast to the print structure of other 3D printing technologies. HARP detailed printing technology can be used in the market including mobile devices, aircraft, dental, orthopedic and even fashion industries.

Mirkin, a professor of chemistry at Northwestern Weinberg, says HARP can be used commercially within the next 18 months.

Productivity and Quality Office