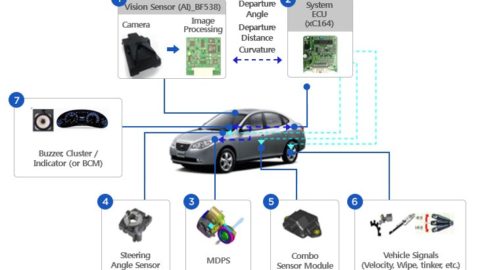

Different modules in the automobile manufacturing process

In the early 2000s, the slogan “Quality is number 1” was lost on the Marketing channel of Ford Motor due to an ever-increasing rate of product complaints and returns. It is estimated that this crisis caused the company to lose $ 5.5 billion in 2001. To solve this problem, the Ford Motor management has carried out an overall improvement plan which is the foundation for Ford’s current success.

The core of Ford’s policy is who they aim for. In the past, too much emphasis on the “quality” factor caused company managers to ignore certain customer needs, while customer support was what made Ford so famous.

“Ford didn’t call his approach lean manufacturing, but he could have,” said Anne Stevens, vice president of operations in North America. “When General Motors introduced a new slogan, ‘a car for everyone and all purposes’, Ford lost its lead in their field and learned an invaluable lesson in choice.”

Talking about this, Mr. Louise Goeser, Ford’s chief quality officer, explains: “In fact, half of customer satisfaction is in their trust in Ford and our data for Seeing that customers are satisfied with Ford products and services and maintaining confidence in the company. “

To solve this problem, the Ford management gently changed General Motors by changing the slogan to “Welcome to the Ford family.” There was no intense competition or marketing, because they understand the core values of the brand year in product and service quality.

“There’s a change going on at Ford, in stark contrast to everything we have come to believe in large-scale industrial production. It represents what is known as the post-industrial era. The change will also usher in a completely new economic era; an era where customers live in a world designed by themselves”, said Anne.

In the past, Ford standardized entire production processes and arranged them vertically linearly. This reduces the burden on workers and improves productivity and delivery times. Under Henry Ford, although he did not know the principles of lean manufacturing, he was able to ensure that any of his workers were able to get acquainted with the new assembly process in just 5 minutes.

However, such a linear process inadvertently reduces production flexibility and makes it difficult for the company to respond to unexpected orders. In addition, the element of personalization in the product also makes Ford reach fewer customers. To solve this problem, it is indispensable to modularize and split the production process into several stages.

(To be continued)

Productivity and Quality Office