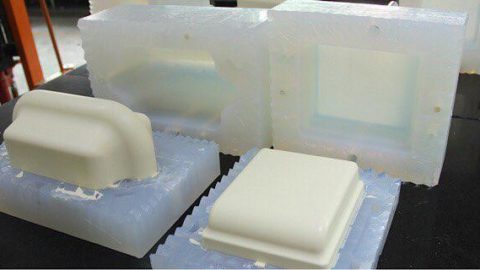

The prototype plastic product is molded using the technology of Waykenrm

The use of CNC machining is a very high efficiency material handling method. This device enables manufacturers to quickly create prototypes of products and to perform fully automated production. Whether your business is just entering the market or has a lot of experience, investing in research into advanced technologies, learning about CNC machines also gives you many advantages in the future.

In general, CNC machining is a preprogrammed manufacturing process. This technology shapes an object by cutting the material into a highly precise shape. The name CNC (Computer Numerical Control) may have been very familiar to many people, but few people know that the technology of this machining method has appeared for a long time. The most surprising fact is that the oldest machine found in Italy dates back to 700 BC.

Until now, this technology still plays one of the most important roles in industrial production. Especially, with the applications of digitization and 4.0 technology, CNC machines are creating a new breakthrough for the field of mechanical processing. Now that some manufacturers have started building their own CNC equipment, many choose to hire these service providers to ensure smooth integration.

Typical is CNC service provider Waykenrm. The company is applying new high-compatibility CNC machining to a wide range of materials. During the research and development process, Waykenrm engineers need to consider factors such as hardness, resistance to heat and chemicals, etc. The company’s new CNC machine has been designed to meet the needs Bridge handles two basic materials: metal and plastic.

Metal materials are more flexible and durable than plastic and can be used for a variety of purposes from prototyping to mass production. Waykenrm’s device uses the laser beam with a concentrated heat source with high heat density to manipulate the material surface. In this way, the machine can produce narrow, sharp, high precision grooves; It is possible to cut in any straight line or curve; The trim edge does not require additional machining steps; The cutting process is quick.

For plastic materials, due to its small weight, good electrical insulation and high impedance, Waykenrm has developed the SLS 3D forming machine with the advantage of saving energy but still producing the product quickly with precision. high body. Some of the commonly used plastic materials are Polycarbon and ABS.

(To be continued)

Productivity and Quality Office