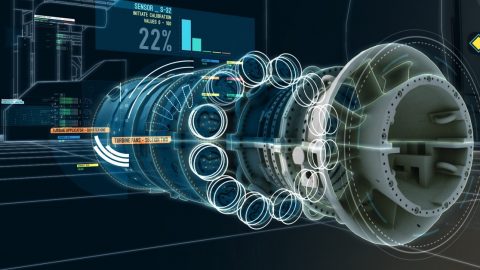

Digital twin model

Today, technology is developing in the direction of high automation, and as a result, the term “hyperautomation” was born. According to the research and consulting firm, this “super-automated” involves the application of advanced technologies including artificial intelligence (AI) and self-learning machines (ML) to enhance processes. automate and help people improve productivity. The combination of tools to create organizations modeling (DTO) to promote real time and new business opportunities.

For packaging businesses, “hyperautomation” appears in the form of integrated modeling with machines in the manufacturing process. And for suppliers, they are also increasingly pushing manufacturing businesses to apply technologies they deem potential.

In August, B&R, a packaging industry, integrated 3D simulation tools into the engineering environment of Automatic Studio. This will allow developers to import CAD data from machine parts to the entire machine directly into simulation tools to create a modeling suite for development and testing. Because the simulation tool is integrated with Automatic Studio, developers can run the virtual model of the machine right on the computer and connect to the controller. This allows viewing of machine performance in real time and whether it can be remedied in a digital model.

B&R has a variety of simulation tools in its product portfolio, all with the goal of shortening the design cycle to speed up time to market. For example, the partnership with Maplesoft has led to the MapleSim B&R connection, creating a simple workflow between the system-level modeling environment (MapleSim) and the automation design environment (B & R Automatic Studio). This connectivity allows designers to create their digital models and test their PLC code in the same process.

B&R uses simulation to show people what the tracking system can do. And in fact, Stacey – product and portfolio management at B&R was able to prove to customers that they are putting a lot of machines into use, and thus, not only helping customers save. money and space, but also give them a full understanding of what they get before ordering.

Productivity and Quality Office