-

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 2)

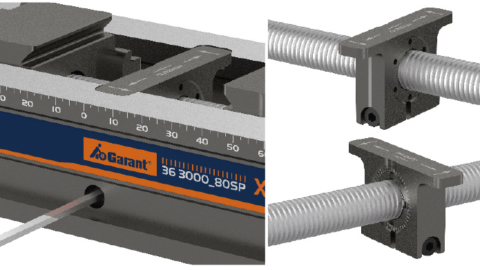

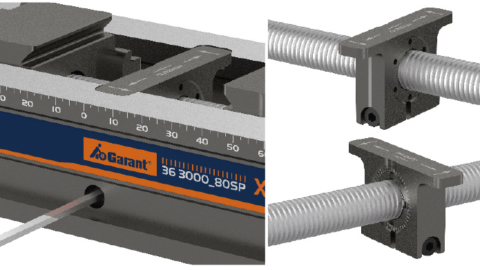

Not only has a flexible design, Hoffman’s Garant Xtric also has a lot of outstanding features. With double spring construction and linear clamping, the clamping force of the device can be up to 25 kN. The special tooth design of Garant Xtric helps to keep and clamp the products, even in...

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 2)

Not only has a flexible design, Hoffman’s Garant Xtric also has a lot of outstanding features. With double spring construction and linear clamping, the clamping force of the device can be up to 25 kN. The special tooth design of Garant Xtric helps to keep and clamp the products, even in...

-

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 1)

In the process of mechanical machining, the jigs to clamp the details, ensuring the machining stability are extremely important. Such clamping and clamping tools are called vents. Currently, many manufacturers are developing their own cars to help improve production capacity. A typical example is the Garant Xtric clamping device researched and...

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 1)

In the process of mechanical machining, the jigs to clamp the details, ensuring the machining stability are extremely important. Such clamping and clamping tools are called vents. Currently, many manufacturers are developing their own cars to help improve production capacity. A typical example is the Garant Xtric clamping device researched and...

-

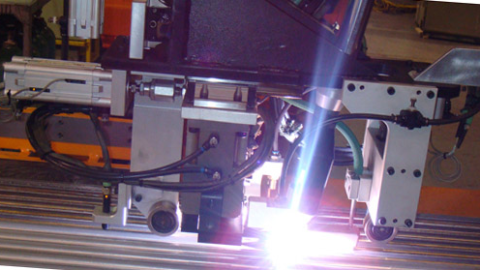

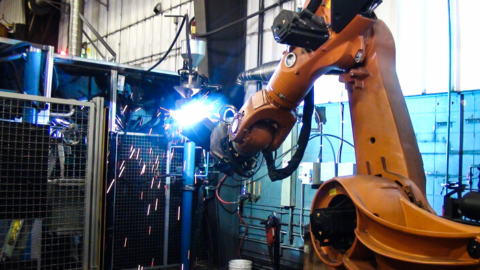

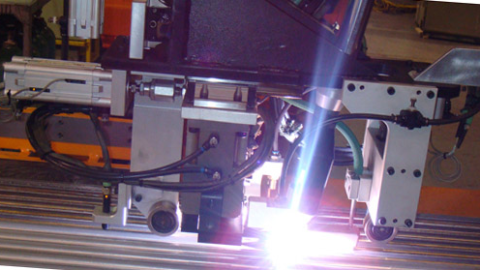

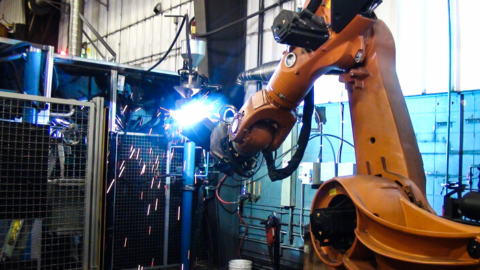

Things your organization should keep in mind when applying welding technology (Part 2) ...

After finishing the process of researching and building a technology investment plan, managers should note the following factors when starting to apply: Ensuring efficiency in material handling Material handling often consumes a lot of time and money, so managers need to respect and devise strategies appropriately to achieve efficiency in this...

Things your organization should keep in mind when applying welding technology (Part 2) ...

After finishing the process of researching and building a technology investment plan, managers should note the following factors when starting to apply: Ensuring efficiency in material handling Material handling often consumes a lot of time and money, so managers need to respect and devise strategies appropriately to achieve efficiency in this...

-

Things your organization should keep in mind when applying welding technology (Part 1) ...

Many manufacturers using mechanical welding technology are unaware that their performance and profitability can be significantly improved with only a few adjustments in the process. With the competitive level of the current mechanical processing industry, product quality is the vital factor for businesses. Accelerating processes while maintaining quality is a difficult...

Things your organization should keep in mind when applying welding technology (Part 1) ...

Many manufacturers using mechanical welding technology are unaware that their performance and profitability can be significantly improved with only a few adjustments in the process. With the competitive level of the current mechanical processing industry, product quality is the vital factor for businesses. Accelerating processes while maintaining quality is a difficult...

-

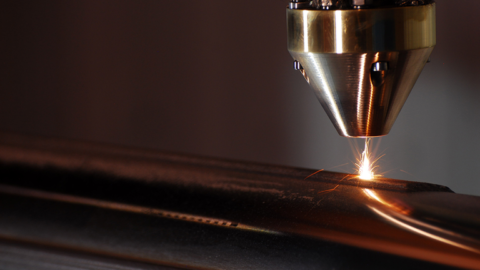

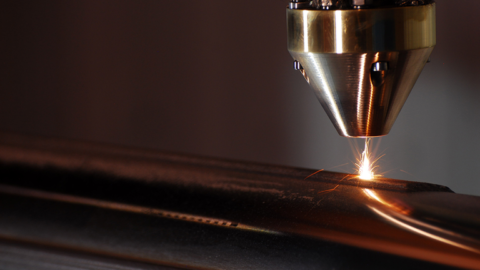

The advantage of laser welding technology in the mechanical processing industry

In the mechanical processing industry, it is extremely important to choose welding technology that matches the properties of the materials. Thanks to scientific and technological advances, laser welding is gradually becoming superior to traditional arc welding methods, both in terms of material compatibility and the ability to integrate new applications. Laser...

The advantage of laser welding technology in the mechanical processing industry

In the mechanical processing industry, it is extremely important to choose welding technology that matches the properties of the materials. Thanks to scientific and technological advances, laser welding is gradually becoming superior to traditional arc welding methods, both in terms of material compatibility and the ability to integrate new applications. Laser...

-

AllTube Engineering: Technological innovation to improve product quality (Part 2)

Besides the support from management systems, technological innovation has also contributed significantly to the success of AllTube Engineering. The first in the transition was to refresh the racking system and rearrange the production area. The racking system with an independent steel structure with dimensions of 6m x 3m x 2.5m has...

AllTube Engineering: Technological innovation to improve product quality (Part 2)

Besides the support from management systems, technological innovation has also contributed significantly to the success of AllTube Engineering. The first in the transition was to refresh the racking system and rearrange the production area. The racking system with an independent steel structure with dimensions of 6m x 3m x 2.5m has...

-

AllTube Engineering: Technological innovation to improve product quality (Part 1)

AllTube Engineering is a historic UK manufacturer of precision mechanical components. Currently the company is providing products for many other fields and industries such as agriculture, construction, trucking and railway. Currently, hydraulic and pneumatic hoses are considered as the flagship products of AllTube Engineering. However, the manufacturing process is having a...

AllTube Engineering: Technological innovation to improve product quality (Part 1)

AllTube Engineering is a historic UK manufacturer of precision mechanical components. Currently the company is providing products for many other fields and industries such as agriculture, construction, trucking and railway. Currently, hydraulic and pneumatic hoses are considered as the flagship products of AllTube Engineering. However, the manufacturing process is having a...

-

Application of 4.0 technology in the JIT production system (Part 1)

Applications of 4.0 technology such as Internet of Things, Big Data and autonomous robots are opening a new direction for the manufacturing industry. In a traditional production environment, the production plan will be defined before the process proceeds. The amount of raw materials “pushed” into each stage is often calculated more...

Application of 4.0 technology in the JIT production system (Part 1)

Applications of 4.0 technology such as Internet of Things, Big Data and autonomous robots are opening a new direction for the manufacturing industry. In a traditional production environment, the production plan will be defined before the process proceeds. The amount of raw materials “pushed” into each stage is often calculated more...

-

Element technology: Solutions for metal manufacturers and manufacturers (Part 2)

There are several important factors to consider before addressing a technology solution for your business. Here are the most important features: Scope of analysis: XRF handheld and LIBS are considered the best complementary technology. Users can combine them to cover a wider range of elements, including light elements (such as carbon)...

Element technology: Solutions for metal manufacturers and manufacturers (Part 2)

There are several important factors to consider before addressing a technology solution for your business. Here are the most important features: Scope of analysis: XRF handheld and LIBS are considered the best complementary technology. Users can combine them to cover a wider range of elements, including light elements (such as carbon)...

-

Element technology: Solutions for metal manufacturers and manufacturers (Part 1)

For many years, metal fabricators have always conducted costly laboratory tests to verify the compatibility of work materials. However, today, advances in elemental analysis technology have helped businesses save a lot of time and money for this stage. Here are some examples: XRF and LIBS analyzers Recently, XRF and LIBS analyzers...

Element technology: Solutions for metal manufacturers and manufacturers (Part 1)

For many years, metal fabricators have always conducted costly laboratory tests to verify the compatibility of work materials. However, today, advances in elemental analysis technology have helped businesses save a lot of time and money for this stage. Here are some examples: XRF and LIBS analyzers Recently, XRF and LIBS analyzers...

Scroll

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 2)

Not only has a flexible design, Hoffman’s Garant Xtric also has a lot of outstanding features. With double spring construction and linear clamping, the clamping force of the device can be up to 25 kN. The special tooth design of Garant Xtric helps to keep and clamp the products, even in...

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 2)

Not only has a flexible design, Hoffman’s Garant Xtric also has a lot of outstanding features. With double spring construction and linear clamping, the clamping force of the device can be up to 25 kN. The special tooth design of Garant Xtric helps to keep and clamp the products, even in...

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 1)

In the process of mechanical machining, the jigs to clamp the details, ensuring the machining stability are extremely important. Such clamping and clamping tools are called vents. Currently, many manufacturers are developing their own cars to help improve production capacity. A typical example is the Garant Xtric clamping device researched and...

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 1)

In the process of mechanical machining, the jigs to clamp the details, ensuring the machining stability are extremely important. Such clamping and clamping tools are called vents. Currently, many manufacturers are developing their own cars to help improve production capacity. A typical example is the Garant Xtric clamping device researched and...

Things your organization should keep in mind when applying welding technology (Part 2) ...

After finishing the process of researching and building a technology investment plan, managers should note the following factors when starting to apply: Ensuring efficiency in material handling Material handling often consumes a lot of time and money, so managers need to respect and devise strategies appropriately to achieve efficiency in this...

Things your organization should keep in mind when applying welding technology (Part 2) ...

After finishing the process of researching and building a technology investment plan, managers should note the following factors when starting to apply: Ensuring efficiency in material handling Material handling often consumes a lot of time and money, so managers need to respect and devise strategies appropriately to achieve efficiency in this...

Things your organization should keep in mind when applying welding technology (Part 1) ...

Many manufacturers using mechanical welding technology are unaware that their performance and profitability can be significantly improved with only a few adjustments in the process. With the competitive level of the current mechanical processing industry, product quality is the vital factor for businesses. Accelerating processes while maintaining quality is a difficult...

Things your organization should keep in mind when applying welding technology (Part 1) ...

Many manufacturers using mechanical welding technology are unaware that their performance and profitability can be significantly improved with only a few adjustments in the process. With the competitive level of the current mechanical processing industry, product quality is the vital factor for businesses. Accelerating processes while maintaining quality is a difficult...

The advantage of laser welding technology in the mechanical processing industry

In the mechanical processing industry, it is extremely important to choose welding technology that matches the properties of the materials. Thanks to scientific and technological advances, laser welding is gradually becoming superior to traditional arc welding methods, both in terms of material compatibility and the ability to integrate new applications. Laser...

The advantage of laser welding technology in the mechanical processing industry

In the mechanical processing industry, it is extremely important to choose welding technology that matches the properties of the materials. Thanks to scientific and technological advances, laser welding is gradually becoming superior to traditional arc welding methods, both in terms of material compatibility and the ability to integrate new applications. Laser...

AllTube Engineering: Technological innovation to improve product quality (Part 2)

Besides the support from management systems, technological innovation has also contributed significantly to the success of AllTube Engineering. The first in the transition was to refresh the racking system and rearrange the production area. The racking system with an independent steel structure with dimensions of 6m x 3m x 2.5m has...

AllTube Engineering: Technological innovation to improve product quality (Part 2)

Besides the support from management systems, technological innovation has also contributed significantly to the success of AllTube Engineering. The first in the transition was to refresh the racking system and rearrange the production area. The racking system with an independent steel structure with dimensions of 6m x 3m x 2.5m has...

AllTube Engineering: Technological innovation to improve product quality (Part 1)

AllTube Engineering is a historic UK manufacturer of precision mechanical components. Currently the company is providing products for many other fields and industries such as agriculture, construction, trucking and railway. Currently, hydraulic and pneumatic hoses are considered as the flagship products of AllTube Engineering. However, the manufacturing process is having a...

AllTube Engineering: Technological innovation to improve product quality (Part 1)

AllTube Engineering is a historic UK manufacturer of precision mechanical components. Currently the company is providing products for many other fields and industries such as agriculture, construction, trucking and railway. Currently, hydraulic and pneumatic hoses are considered as the flagship products of AllTube Engineering. However, the manufacturing process is having a...

Application of 4.0 technology in the JIT production system (Part 1)

Applications of 4.0 technology such as Internet of Things, Big Data and autonomous robots are opening a new direction for the manufacturing industry. In a traditional production environment, the production plan will be defined before the process proceeds. The amount of raw materials “pushed” into each stage is often calculated more...

Application of 4.0 technology in the JIT production system (Part 1)

Applications of 4.0 technology such as Internet of Things, Big Data and autonomous robots are opening a new direction for the manufacturing industry. In a traditional production environment, the production plan will be defined before the process proceeds. The amount of raw materials “pushed” into each stage is often calculated more...

Element technology: Solutions for metal manufacturers and manufacturers (Part 2)

There are several important factors to consider before addressing a technology solution for your business. Here are the most important features: Scope of analysis: XRF handheld and LIBS are considered the best complementary technology. Users can combine them to cover a wider range of elements, including light elements (such as carbon)...

Element technology: Solutions for metal manufacturers and manufacturers (Part 2)

There are several important factors to consider before addressing a technology solution for your business. Here are the most important features: Scope of analysis: XRF handheld and LIBS are considered the best complementary technology. Users can combine them to cover a wider range of elements, including light elements (such as carbon)...

Element technology: Solutions for metal manufacturers and manufacturers (Part 1)

For many years, metal fabricators have always conducted costly laboratory tests to verify the compatibility of work materials. However, today, advances in elemental analysis technology have helped businesses save a lot of time and money for this stage. Here are some examples: XRF and LIBS analyzers Recently, XRF and LIBS analyzers...

Element technology: Solutions for metal manufacturers and manufacturers (Part 1)

For many years, metal fabricators have always conducted costly laboratory tests to verify the compatibility of work materials. However, today, advances in elemental analysis technology have helped businesses save a lot of time and money for this stage. Here are some examples: XRF and LIBS analyzers Recently, XRF and LIBS analyzers...