-

Production of super hardened steel by 3D printing technology

The high corrosion and rust resistant steel production process, withstand temperatures of 750 degrees Celsius is shortened, because it is “printed” literally by 3D printing technology. VBN Components company, based in Uppsala city, 70km north of Sweden’s capital Stockholm, “printed” a kind of superhard steel called Vibenite 480. This company has...

Production of super hardened steel by 3D printing technology

The high corrosion and rust resistant steel production process, withstand temperatures of 750 degrees Celsius is shortened, because it is “printed” literally by 3D printing technology. VBN Components company, based in Uppsala city, 70km north of Sweden’s capital Stockholm, “printed” a kind of superhard steel called Vibenite 480. This company has...

-

Application of technology to enhance the value of FMCG (Part 1)

FMCG companies are leveraging technology to beat long-term challenges and build emerging opportunities in a developed market. Having no inventory at retailers and making new products quickly available is crucial for FMCG companies. An effective network to push a often perishable cargo pipeline is also key. In addition, they must ensure...

Application of technology to enhance the value of FMCG (Part 1)

FMCG companies are leveraging technology to beat long-term challenges and build emerging opportunities in a developed market. Having no inventory at retailers and making new products quickly available is crucial for FMCG companies. An effective network to push a often perishable cargo pipeline is also key. In addition, they must ensure...

-

12 tools to improve manager productivity (Part 2)

Besides information exchange and workflow monitoring tools, many other types of tools are also being used and recognized by many famous managers in the world. Tracker and calendar reminder 6. Calendly Calendly is a popular option for those who want to cut down on email while scheduling meetings. “I use Calendly...

12 tools to improve manager productivity (Part 2)

Besides information exchange and workflow monitoring tools, many other types of tools are also being used and recognized by many famous managers in the world. Tracker and calendar reminder 6. Calendly Calendly is a popular option for those who want to cut down on email while scheduling meetings. “I use Calendly...

-

How is technology able to increase productivity in manufacturing? (Part 2)

Drones Drones can impact a company massively, saving almost 12 hours on each inspection and reducing the time it takes to check the equipment from 12 hours to 12 minutes. Not only can drones provide a quick and thorough inspection, but they eliminate the health and safety risk of someone needing...

How is technology able to increase productivity in manufacturing? (Part 2)

Drones Drones can impact a company massively, saving almost 12 hours on each inspection and reducing the time it takes to check the equipment from 12 hours to 12 minutes. Not only can drones provide a quick and thorough inspection, but they eliminate the health and safety risk of someone needing...

-

How is technology able to increase productivity in manufacturing? (Part 1)

Computer systems, such as CRMs and warehouse management systems, can help you plan out your workload as efficiently as possible to increase productivity of staff, while analytics allow you to judge what updates are needed and when. Whether it’s the food takeaway industry utilising mobile apps or sports events using video-assisted...

How is technology able to increase productivity in manufacturing? (Part 1)

Computer systems, such as CRMs and warehouse management systems, can help you plan out your workload as efficiently as possible to increase productivity of staff, while analytics allow you to judge what updates are needed and when. Whether it’s the food takeaway industry utilising mobile apps or sports events using video-assisted...

-

12 tools to improve manager productivity (Part 1)

Through the support of modern applications, managers can manage their work and time effectively, at the same time increase productivity while still taking a reasonable break. Human’s time and energy are finite, that’s the truth. You cannot have more than 24 hours a day and your body no matter how strong...

12 tools to improve manager productivity (Part 1)

Through the support of modern applications, managers can manage their work and time effectively, at the same time increase productivity while still taking a reasonable break. Human’s time and energy are finite, that’s the truth. You cannot have more than 24 hours a day and your body no matter how strong...

-

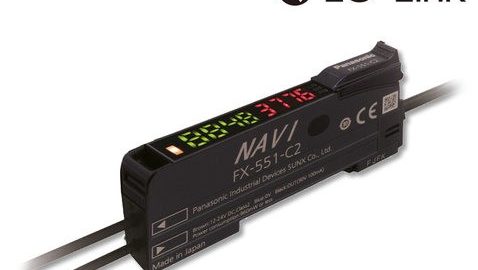

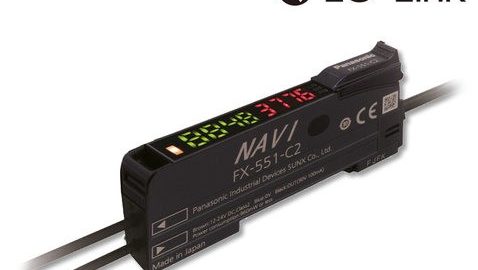

Sensor technology developed for quality control (Part 3)

Today, dual sensor technology combined with IO-Link helps users control product quality effectively, easily estimate the time of sensor maintenance, replace easily during use and help reduce cost. Cost reducing Using stronger, smarter sensors allows manufacturers to tackle more applications with fewer devices, reducing upfront costs and long-term costs to maintain...

Sensor technology developed for quality control (Part 3)

Today, dual sensor technology combined with IO-Link helps users control product quality effectively, easily estimate the time of sensor maintenance, replace easily during use and help reduce cost. Cost reducing Using stronger, smarter sensors allows manufacturers to tackle more applications with fewer devices, reducing upfront costs and long-term costs to maintain...

-

5 solutions for switching technology in storage

Today, disruptive technologies have allowed a new breed of warehouse management systems (WMS) to evolve, removing the constant need for human intervention. Instead of requiring human operators, most machinery can manage itself. Rather than working on the ‘man-to-goods’ principle, in which human employees ferry products from place to place, automated systems...

5 solutions for switching technology in storage

Today, disruptive technologies have allowed a new breed of warehouse management systems (WMS) to evolve, removing the constant need for human intervention. Instead of requiring human operators, most machinery can manage itself. Rather than working on the ‘man-to-goods’ principle, in which human employees ferry products from place to place, automated systems...

-

Sensor technology developed for quality control (Part 2)

Thanks to advances in laser metering technology, sensors can now measure tougher targets (including clear, reflective and low-contrast targets) and can handle a wide variety of testing tasks. Look up with only one sensor. In addition, with IO-Link communication, monitoring the performance of the sensor becomes easier, identifying trends in test...

Sensor technology developed for quality control (Part 2)

Thanks to advances in laser metering technology, sensors can now measure tougher targets (including clear, reflective and low-contrast targets) and can handle a wide variety of testing tasks. Look up with only one sensor. In addition, with IO-Link communication, monitoring the performance of the sensor becomes easier, identifying trends in test...

-

Sensor technology developed for quality control (Part 1)

Advances in laser measurement technology and the adoption of IO-Link communication are making complex testing easier, more reliable, and more cost-effective. Fast, reliable error proofing is essential to ensure consistent throughput without loss of quality. Manual quality checks can often be boring, distracting to performers and at the same time prone...

Sensor technology developed for quality control (Part 1)

Advances in laser measurement technology and the adoption of IO-Link communication are making complex testing easier, more reliable, and more cost-effective. Fast, reliable error proofing is essential to ensure consistent throughput without loss of quality. Manual quality checks can often be boring, distracting to performers and at the same time prone...

Scroll

Production of super hardened steel by 3D printing technology

The high corrosion and rust resistant steel production process, withstand temperatures of 750 degrees Celsius is shortened, because it is “printed” literally by 3D printing technology. VBN Components company, based in Uppsala city, 70km north of Sweden’s capital Stockholm, “printed” a kind of superhard steel called Vibenite 480. This company has...

Production of super hardened steel by 3D printing technology

The high corrosion and rust resistant steel production process, withstand temperatures of 750 degrees Celsius is shortened, because it is “printed” literally by 3D printing technology. VBN Components company, based in Uppsala city, 70km north of Sweden’s capital Stockholm, “printed” a kind of superhard steel called Vibenite 480. This company has...

Application of technology to enhance the value of FMCG (Part 1)

FMCG companies are leveraging technology to beat long-term challenges and build emerging opportunities in a developed market. Having no inventory at retailers and making new products quickly available is crucial for FMCG companies. An effective network to push a often perishable cargo pipeline is also key. In addition, they must ensure...

Application of technology to enhance the value of FMCG (Part 1)

FMCG companies are leveraging technology to beat long-term challenges and build emerging opportunities in a developed market. Having no inventory at retailers and making new products quickly available is crucial for FMCG companies. An effective network to push a often perishable cargo pipeline is also key. In addition, they must ensure...

12 tools to improve manager productivity (Part 2)

Besides information exchange and workflow monitoring tools, many other types of tools are also being used and recognized by many famous managers in the world. Tracker and calendar reminder 6. Calendly Calendly is a popular option for those who want to cut down on email while scheduling meetings. “I use Calendly...

12 tools to improve manager productivity (Part 2)

Besides information exchange and workflow monitoring tools, many other types of tools are also being used and recognized by many famous managers in the world. Tracker and calendar reminder 6. Calendly Calendly is a popular option for those who want to cut down on email while scheduling meetings. “I use Calendly...

How is technology able to increase productivity in manufacturing? (Part 2)

Drones Drones can impact a company massively, saving almost 12 hours on each inspection and reducing the time it takes to check the equipment from 12 hours to 12 minutes. Not only can drones provide a quick and thorough inspection, but they eliminate the health and safety risk of someone needing...

How is technology able to increase productivity in manufacturing? (Part 2)

Drones Drones can impact a company massively, saving almost 12 hours on each inspection and reducing the time it takes to check the equipment from 12 hours to 12 minutes. Not only can drones provide a quick and thorough inspection, but they eliminate the health and safety risk of someone needing...

How is technology able to increase productivity in manufacturing? (Part 1)

Computer systems, such as CRMs and warehouse management systems, can help you plan out your workload as efficiently as possible to increase productivity of staff, while analytics allow you to judge what updates are needed and when. Whether it’s the food takeaway industry utilising mobile apps or sports events using video-assisted...

How is technology able to increase productivity in manufacturing? (Part 1)

Computer systems, such as CRMs and warehouse management systems, can help you plan out your workload as efficiently as possible to increase productivity of staff, while analytics allow you to judge what updates are needed and when. Whether it’s the food takeaway industry utilising mobile apps or sports events using video-assisted...

12 tools to improve manager productivity (Part 1)

Through the support of modern applications, managers can manage their work and time effectively, at the same time increase productivity while still taking a reasonable break. Human’s time and energy are finite, that’s the truth. You cannot have more than 24 hours a day and your body no matter how strong...

12 tools to improve manager productivity (Part 1)

Through the support of modern applications, managers can manage their work and time effectively, at the same time increase productivity while still taking a reasonable break. Human’s time and energy are finite, that’s the truth. You cannot have more than 24 hours a day and your body no matter how strong...

Sensor technology developed for quality control (Part 3)

Today, dual sensor technology combined with IO-Link helps users control product quality effectively, easily estimate the time of sensor maintenance, replace easily during use and help reduce cost. Cost reducing Using stronger, smarter sensors allows manufacturers to tackle more applications with fewer devices, reducing upfront costs and long-term costs to maintain...

Sensor technology developed for quality control (Part 3)

Today, dual sensor technology combined with IO-Link helps users control product quality effectively, easily estimate the time of sensor maintenance, replace easily during use and help reduce cost. Cost reducing Using stronger, smarter sensors allows manufacturers to tackle more applications with fewer devices, reducing upfront costs and long-term costs to maintain...

5 solutions for switching technology in storage

Today, disruptive technologies have allowed a new breed of warehouse management systems (WMS) to evolve, removing the constant need for human intervention. Instead of requiring human operators, most machinery can manage itself. Rather than working on the ‘man-to-goods’ principle, in which human employees ferry products from place to place, automated systems...

5 solutions for switching technology in storage

Today, disruptive technologies have allowed a new breed of warehouse management systems (WMS) to evolve, removing the constant need for human intervention. Instead of requiring human operators, most machinery can manage itself. Rather than working on the ‘man-to-goods’ principle, in which human employees ferry products from place to place, automated systems...

Sensor technology developed for quality control (Part 2)

Thanks to advances in laser metering technology, sensors can now measure tougher targets (including clear, reflective and low-contrast targets) and can handle a wide variety of testing tasks. Look up with only one sensor. In addition, with IO-Link communication, monitoring the performance of the sensor becomes easier, identifying trends in test...

Sensor technology developed for quality control (Part 2)

Thanks to advances in laser metering technology, sensors can now measure tougher targets (including clear, reflective and low-contrast targets) and can handle a wide variety of testing tasks. Look up with only one sensor. In addition, with IO-Link communication, monitoring the performance of the sensor becomes easier, identifying trends in test...

Sensor technology developed for quality control (Part 1)

Advances in laser measurement technology and the adoption of IO-Link communication are making complex testing easier, more reliable, and more cost-effective. Fast, reliable error proofing is essential to ensure consistent throughput without loss of quality. Manual quality checks can often be boring, distracting to performers and at the same time prone...

Sensor technology developed for quality control (Part 1)

Advances in laser measurement technology and the adoption of IO-Link communication are making complex testing easier, more reliable, and more cost-effective. Fast, reliable error proofing is essential to ensure consistent throughput without loss of quality. Manual quality checks can often be boring, distracting to performers and at the same time prone...