-

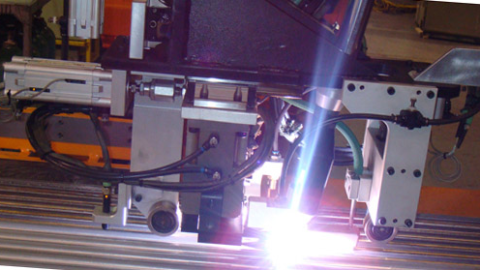

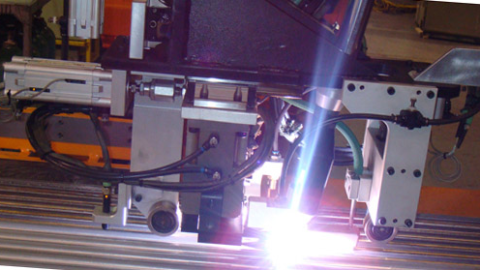

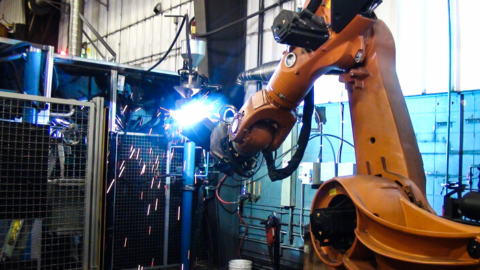

Things your organization should keep in mind when applying welding technology (Part 2) ...

After finishing the process of researching and building a technology investment plan, managers should note the following factors when starting to apply: Ensuring efficiency in material handling Material handling often consumes a lot of time and money, so managers need to respect and devise strategies appropriately to achieve efficiency in this...

Things your organization should keep in mind when applying welding technology (Part 2) ...

After finishing the process of researching and building a technology investment plan, managers should note the following factors when starting to apply: Ensuring efficiency in material handling Material handling often consumes a lot of time and money, so managers need to respect and devise strategies appropriately to achieve efficiency in this...

-

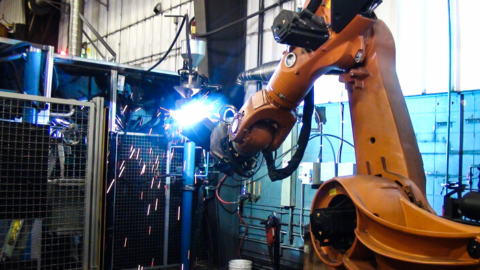

Things your organization should keep in mind when applying welding technology (Part 1) ...

Many manufacturers using mechanical welding technology are unaware that their performance and profitability can be significantly improved with only a few adjustments in the process. With the competitive level of the current mechanical processing industry, product quality is the vital factor for businesses. Accelerating processes while maintaining quality is a difficult...

Things your organization should keep in mind when applying welding technology (Part 1) ...

Many manufacturers using mechanical welding technology are unaware that their performance and profitability can be significantly improved with only a few adjustments in the process. With the competitive level of the current mechanical processing industry, product quality is the vital factor for businesses. Accelerating processes while maintaining quality is a difficult...

-

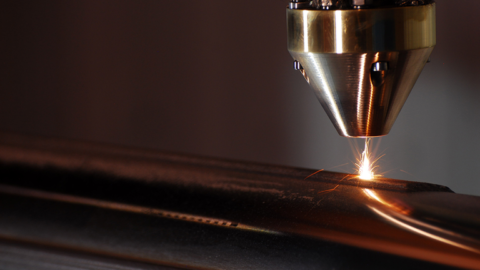

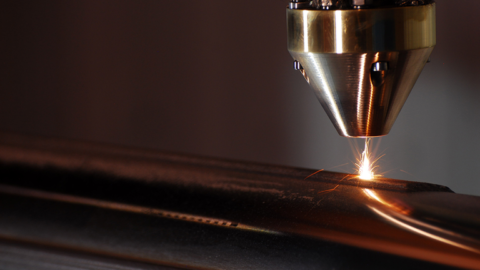

The advantage of laser welding technology in the mechanical processing industry

In the mechanical processing industry, it is extremely important to choose welding technology that matches the properties of the materials. Thanks to scientific and technological advances, laser welding is gradually becoming superior to traditional arc welding methods, both in terms of material compatibility and the ability to integrate new applications. Laser...

The advantage of laser welding technology in the mechanical processing industry

In the mechanical processing industry, it is extremely important to choose welding technology that matches the properties of the materials. Thanks to scientific and technological advances, laser welding is gradually becoming superior to traditional arc welding methods, both in terms of material compatibility and the ability to integrate new applications. Laser...

-

Aerospace supplier reduces production process from 90 hours to 18

A Lancashire-based precision engineering company, which supplies to the LEAP aircraft engine, has reduced production time drastically by installing Industry 4.0 technologies. T&R Precision was incorporated over 20 years ago by father and son engineers Ray and Tim Maddison and has grown to be a key part of the supply chain...

Aerospace supplier reduces production process from 90 hours to 18

A Lancashire-based precision engineering company, which supplies to the LEAP aircraft engine, has reduced production time drastically by installing Industry 4.0 technologies. T&R Precision was incorporated over 20 years ago by father and son engineers Ray and Tim Maddison and has grown to be a key part of the supply chain...

-

AllTube Engineering: Technological innovation to improve product quality (Part 2)

Besides the support from management systems, technological innovation has also contributed significantly to the success of AllTube Engineering. The first in the transition was to refresh the racking system and rearrange the production area. The racking system with an independent steel structure with dimensions of 6m x 3m x 2.5m has...

AllTube Engineering: Technological innovation to improve product quality (Part 2)

Besides the support from management systems, technological innovation has also contributed significantly to the success of AllTube Engineering. The first in the transition was to refresh the racking system and rearrange the production area. The racking system with an independent steel structure with dimensions of 6m x 3m x 2.5m has...

-

AllTube Engineering: Technological innovation to improve product quality (Part 1)

AllTube Engineering is a historic UK manufacturer of precision mechanical components. Currently the company is providing products for many other fields and industries such as agriculture, construction, trucking and railway. Currently, hydraulic and pneumatic hoses are considered as the flagship products of AllTube Engineering. However, the manufacturing process is having a...

AllTube Engineering: Technological innovation to improve product quality (Part 1)

AllTube Engineering is a historic UK manufacturer of precision mechanical components. Currently the company is providing products for many other fields and industries such as agriculture, construction, trucking and railway. Currently, hydraulic and pneumatic hoses are considered as the flagship products of AllTube Engineering. However, the manufacturing process is having a...

-

Factors influencing your factory choice of CNC equipment (Part 3)

The continuous development of technology has brought many breakthrough achievements for many manufacturing industries in the world, and the field of precision machining is no exception. The achievements in digitization and automation are now having a strong impact on the production efficiency of enterprises that are applying new generation CNC equipment....

Factors influencing your factory choice of CNC equipment (Part 3)

The continuous development of technology has brought many breakthrough achievements for many manufacturing industries in the world, and the field of precision machining is no exception. The achievements in digitization and automation are now having a strong impact on the production efficiency of enterprises that are applying new generation CNC equipment....

-

Kyodai improved productivity and promoted internal training activities

With initial encouraging results when implementing the pillars of Autonomous Maintenance and Maintenance according to the Plan, Kyodai Manufacturing Joint Stock Company has implemented key improvement activities on productivity – quality issuest as the company set out. The company’s production data collection is maintained for all machinery and equipment. These data...

Kyodai improved productivity and promoted internal training activities

With initial encouraging results when implementing the pillars of Autonomous Maintenance and Maintenance according to the Plan, Kyodai Manufacturing Joint Stock Company has implemented key improvement activities on productivity – quality issuest as the company set out. The company’s production data collection is maintained for all machinery and equipment. These data...

-

Evaluation of TPM team on TPM implementation results at Hong Ha Shipbuilding

Since April 2019, Hong Ha Shipbuilding Co., Ltd. has started to deploy TPM under the support program of Department of Science and Technology, Ministry of Industry and Trade. TPM targets are set for each workshop in the factory (M&E workshop, Shipbuilding workshop, M&E workshop and Motivation workshop) to achieve a common...

Evaluation of TPM team on TPM implementation results at Hong Ha Shipbuilding

Since April 2019, Hong Ha Shipbuilding Co., Ltd. has started to deploy TPM under the support program of Department of Science and Technology, Ministry of Industry and Trade. TPM targets are set for each workshop in the factory (M&E workshop, Shipbuilding workshop, M&E workshop and Motivation workshop) to achieve a common...

-

JAT is constantly improving to increase productivity and product quality

JAT Automobile Spare Parts and Industrial Equipment Joint Stock Company was established on January 25, 2008. Currently, the company’s factory is located at: Lot II – 8.2 Que Vo industrial package – Ngoc Xa Commune – Que Vo District – Bac Ninh Province. With the vision of building JAT to become...

JAT is constantly improving to increase productivity and product quality

JAT Automobile Spare Parts and Industrial Equipment Joint Stock Company was established on January 25, 2008. Currently, the company’s factory is located at: Lot II – 8.2 Que Vo industrial package – Ngoc Xa Commune – Que Vo District – Bac Ninh Province. With the vision of building JAT to become...

Scroll

Things your organization should keep in mind when applying welding technology (Part 2) ...

After finishing the process of researching and building a technology investment plan, managers should note the following factors when starting to apply: Ensuring efficiency in material handling Material handling often consumes a lot of time and money, so managers need to respect and devise strategies appropriately to achieve efficiency in this...

Things your organization should keep in mind when applying welding technology (Part 2) ...

After finishing the process of researching and building a technology investment plan, managers should note the following factors when starting to apply: Ensuring efficiency in material handling Material handling often consumes a lot of time and money, so managers need to respect and devise strategies appropriately to achieve efficiency in this...

Things your organization should keep in mind when applying welding technology (Part 1) ...

Many manufacturers using mechanical welding technology are unaware that their performance and profitability can be significantly improved with only a few adjustments in the process. With the competitive level of the current mechanical processing industry, product quality is the vital factor for businesses. Accelerating processes while maintaining quality is a difficult...

Things your organization should keep in mind when applying welding technology (Part 1) ...

Many manufacturers using mechanical welding technology are unaware that their performance and profitability can be significantly improved with only a few adjustments in the process. With the competitive level of the current mechanical processing industry, product quality is the vital factor for businesses. Accelerating processes while maintaining quality is a difficult...

The advantage of laser welding technology in the mechanical processing industry

In the mechanical processing industry, it is extremely important to choose welding technology that matches the properties of the materials. Thanks to scientific and technological advances, laser welding is gradually becoming superior to traditional arc welding methods, both in terms of material compatibility and the ability to integrate new applications. Laser...

The advantage of laser welding technology in the mechanical processing industry

In the mechanical processing industry, it is extremely important to choose welding technology that matches the properties of the materials. Thanks to scientific and technological advances, laser welding is gradually becoming superior to traditional arc welding methods, both in terms of material compatibility and the ability to integrate new applications. Laser...

Aerospace supplier reduces production process from 90 hours to 18

A Lancashire-based precision engineering company, which supplies to the LEAP aircraft engine, has reduced production time drastically by installing Industry 4.0 technologies. T&R Precision was incorporated over 20 years ago by father and son engineers Ray and Tim Maddison and has grown to be a key part of the supply chain...

Aerospace supplier reduces production process from 90 hours to 18

A Lancashire-based precision engineering company, which supplies to the LEAP aircraft engine, has reduced production time drastically by installing Industry 4.0 technologies. T&R Precision was incorporated over 20 years ago by father and son engineers Ray and Tim Maddison and has grown to be a key part of the supply chain...

AllTube Engineering: Technological innovation to improve product quality (Part 2)

Besides the support from management systems, technological innovation has also contributed significantly to the success of AllTube Engineering. The first in the transition was to refresh the racking system and rearrange the production area. The racking system with an independent steel structure with dimensions of 6m x 3m x 2.5m has...

AllTube Engineering: Technological innovation to improve product quality (Part 2)

Besides the support from management systems, technological innovation has also contributed significantly to the success of AllTube Engineering. The first in the transition was to refresh the racking system and rearrange the production area. The racking system with an independent steel structure with dimensions of 6m x 3m x 2.5m has...

AllTube Engineering: Technological innovation to improve product quality (Part 1)

AllTube Engineering is a historic UK manufacturer of precision mechanical components. Currently the company is providing products for many other fields and industries such as agriculture, construction, trucking and railway. Currently, hydraulic and pneumatic hoses are considered as the flagship products of AllTube Engineering. However, the manufacturing process is having a...

AllTube Engineering: Technological innovation to improve product quality (Part 1)

AllTube Engineering is a historic UK manufacturer of precision mechanical components. Currently the company is providing products for many other fields and industries such as agriculture, construction, trucking and railway. Currently, hydraulic and pneumatic hoses are considered as the flagship products of AllTube Engineering. However, the manufacturing process is having a...

Factors influencing your factory choice of CNC equipment (Part 3)

The continuous development of technology has brought many breakthrough achievements for many manufacturing industries in the world, and the field of precision machining is no exception. The achievements in digitization and automation are now having a strong impact on the production efficiency of enterprises that are applying new generation CNC equipment....

Factors influencing your factory choice of CNC equipment (Part 3)

The continuous development of technology has brought many breakthrough achievements for many manufacturing industries in the world, and the field of precision machining is no exception. The achievements in digitization and automation are now having a strong impact on the production efficiency of enterprises that are applying new generation CNC equipment....

Kyodai improved productivity and promoted internal training activities

With initial encouraging results when implementing the pillars of Autonomous Maintenance and Maintenance according to the Plan, Kyodai Manufacturing Joint Stock Company has implemented key improvement activities on productivity – quality issuest as the company set out. The company’s production data collection is maintained for all machinery and equipment. These data...

Kyodai improved productivity and promoted internal training activities

With initial encouraging results when implementing the pillars of Autonomous Maintenance and Maintenance according to the Plan, Kyodai Manufacturing Joint Stock Company has implemented key improvement activities on productivity – quality issuest as the company set out. The company’s production data collection is maintained for all machinery and equipment. These data...

Evaluation of TPM team on TPM implementation results at Hong Ha Shipbuilding

Since April 2019, Hong Ha Shipbuilding Co., Ltd. has started to deploy TPM under the support program of Department of Science and Technology, Ministry of Industry and Trade. TPM targets are set for each workshop in the factory (M&E workshop, Shipbuilding workshop, M&E workshop and Motivation workshop) to achieve a common...

Evaluation of TPM team on TPM implementation results at Hong Ha Shipbuilding

Since April 2019, Hong Ha Shipbuilding Co., Ltd. has started to deploy TPM under the support program of Department of Science and Technology, Ministry of Industry and Trade. TPM targets are set for each workshop in the factory (M&E workshop, Shipbuilding workshop, M&E workshop and Motivation workshop) to achieve a common...

JAT is constantly improving to increase productivity and product quality

JAT Automobile Spare Parts and Industrial Equipment Joint Stock Company was established on January 25, 2008. Currently, the company’s factory is located at: Lot II – 8.2 Que Vo industrial package – Ngoc Xa Commune – Que Vo District – Bac Ninh Province. With the vision of building JAT to become...

JAT is constantly improving to increase productivity and product quality

JAT Automobile Spare Parts and Industrial Equipment Joint Stock Company was established on January 25, 2008. Currently, the company’s factory is located at: Lot II – 8.2 Que Vo industrial package – Ngoc Xa Commune – Que Vo District – Bac Ninh Province. With the vision of building JAT to become...