-

Experience of successfully applying TPM at Valvetrain Components Ltd

Valve Train Components Ltd (VTC) is one of the leading suppliers of valve collets and synchromesh sliding keys to the global automotive market. A first tier supplier to many of the world’s premier automotive companies, it manufactures over 300 million valve collets per annum and exports to more than 20 countries...

Experience of successfully applying TPM at Valvetrain Components Ltd

Valve Train Components Ltd (VTC) is one of the leading suppliers of valve collets and synchromesh sliding keys to the global automotive market. A first tier supplier to many of the world’s premier automotive companies, it manufactures over 300 million valve collets per annum and exports to more than 20 countries...

-

Factors influencing your factory choice of CNC equipment (Part 2)

Besides the material, the type and the intended use of the CNC machine also play an important role in helping manufacturers choose the right equipment for their production model. Today, CNC machine models are constantly changing to meet market demand. The new generation CNC machines are mainly divided into 3-axis or...

Factors influencing your factory choice of CNC equipment (Part 2)

Besides the material, the type and the intended use of the CNC machine also play an important role in helping manufacturers choose the right equipment for their production model. Today, CNC machine models are constantly changing to meet market demand. The new generation CNC machines are mainly divided into 3-axis or...

-

Leyland Trucks successfully applying Lean manufacturing

Leyland Trucks manufactures the full range of DAF Trucks, from 7.5 to 44 tonnes, at its facility in Leyland. All vehicles are produced on one line at a rate of 20,000 per year. The facility operates in line with the Paccar Production System (PPS) and Leyland Trucks is one of the...

Leyland Trucks successfully applying Lean manufacturing

Leyland Trucks manufactures the full range of DAF Trucks, from 7.5 to 44 tonnes, at its facility in Leyland. All vehicles are produced on one line at a rate of 20,000 per year. The facility operates in line with the Paccar Production System (PPS) and Leyland Trucks is one of the...

-

MRT Castings: Promote technological innovation and management system adoption (Part 2)

One of the outstanding technology applications that has helped MRT Castings significantly improve productivity and product quality is Brother’s Speedio M140X2. With the Speedio M140X2, raw materials entering the new Brother machine are fed automatically from the Feedio robot handling system, including the casting and the workpiece being fed into the...

MRT Castings: Promote technological innovation and management system adoption (Part 2)

One of the outstanding technology applications that has helped MRT Castings significantly improve productivity and product quality is Brother’s Speedio M140X2. With the Speedio M140X2, raw materials entering the new Brother machine are fed automatically from the Feedio robot handling system, including the casting and the workpiece being fed into the...

-

MRT Castings: Promoting technological innovation and management system adoption (Part 1)

MRT Castings is a long-established UK-based company specializing in gravity casting and machine building, with over 70 years of industry experience. Currently the company’s products are present in many regions around the world such as North America, Western Europe, Central Asia, the Middle East and Africa, etc. With the aim of...

MRT Castings: Promoting technological innovation and management system adoption (Part 1)

MRT Castings is a long-established UK-based company specializing in gravity casting and machine building, with over 70 years of industry experience. Currently the company’s products are present in many regions around the world such as North America, Western Europe, Central Asia, the Middle East and Africa, etc. With the aim of...

-

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 3)

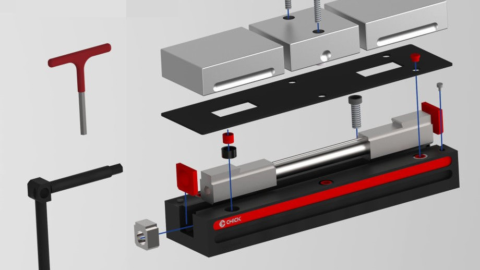

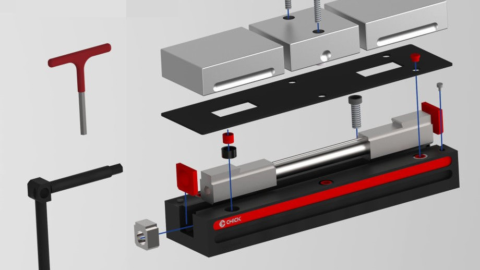

When it comes to the advantages of the Qwik-Lok vise clamps over traditional clamps, the Qwik-Lok’s short set-up time is arguably the most outstanding. In the past, standard wound rollers were used to fix machining parts on CNC machining machines and centers, but as the production intensity increased, these ethers gradually...

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 3)

When it comes to the advantages of the Qwik-Lok vise clamps over traditional clamps, the Qwik-Lok’s short set-up time is arguably the most outstanding. In the past, standard wound rollers were used to fix machining parts on CNC machining machines and centers, but as the production intensity increased, these ethers gradually...

-

VINGAL-VNSTEEL: Increasing competitiveness thanks to quality

Operating in the context of fierce competition market, VINGAL-VNSTEEL Industrial Galvanized Joint Stock Company has been continuously investing in technology and improving product quality to increase competitiveness. With a long tradition of over 24 years of construction and development, VINGAL-VNSTEEL Industrial Galvanized Joint Stock Company specializes in manufacturing and trading in...

VINGAL-VNSTEEL: Increasing competitiveness thanks to quality

Operating in the context of fierce competition market, VINGAL-VNSTEEL Industrial Galvanized Joint Stock Company has been continuously investing in technology and improving product quality to increase competitiveness. With a long tradition of over 24 years of construction and development, VINGAL-VNSTEEL Industrial Galvanized Joint Stock Company specializes in manufacturing and trading in...

-

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 2)

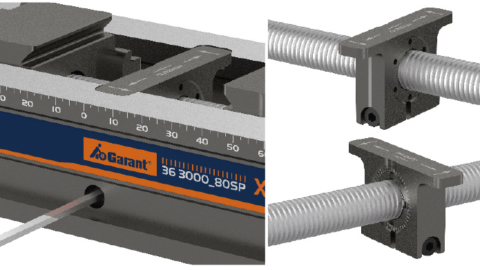

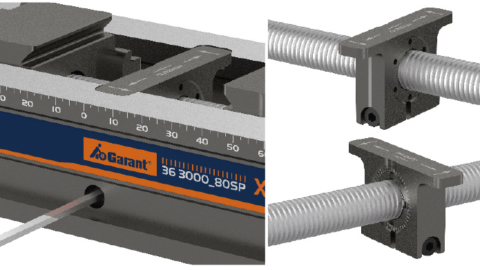

Not only has a flexible design, Hoffman’s Garant Xtric also has a lot of outstanding features. With double spring construction and linear clamping, the clamping force of the device can be up to 25 kN. The special tooth design of Garant Xtric helps to keep and clamp the products, even in...

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 2)

Not only has a flexible design, Hoffman’s Garant Xtric also has a lot of outstanding features. With double spring construction and linear clamping, the clamping force of the device can be up to 25 kN. The special tooth design of Garant Xtric helps to keep and clamp the products, even in...

-

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 1)

In the process of mechanical machining, the jigs to clamp the details, ensuring the machining stability are extremely important. Such clamping and clamping tools are called vents. Currently, many manufacturers are developing their own cars to help improve production capacity. A typical example is the Garant Xtric clamping device researched and...

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 1)

In the process of mechanical machining, the jigs to clamp the details, ensuring the machining stability are extremely important. Such clamping and clamping tools are called vents. Currently, many manufacturers are developing their own cars to help improve production capacity. A typical example is the Garant Xtric clamping device researched and...

-

At the cutting edge of continuous improvement

1 million parts per month, from brackets to fully functioning coffee machines. An average batch size of just 36 parts and the introduction of 450 new parts per month. Yet the employees at this fast moving engineering firm still found time to save £435,000 last year. I went to catch up...

At the cutting edge of continuous improvement

1 million parts per month, from brackets to fully functioning coffee machines. An average batch size of just 36 parts and the introduction of 450 new parts per month. Yet the employees at this fast moving engineering firm still found time to save £435,000 last year. I went to catch up...

Scroll

Experience of successfully applying TPM at Valvetrain Components Ltd

Valve Train Components Ltd (VTC) is one of the leading suppliers of valve collets and synchromesh sliding keys to the global automotive market. A first tier supplier to many of the world’s premier automotive companies, it manufactures over 300 million valve collets per annum and exports to more than 20 countries...

Experience of successfully applying TPM at Valvetrain Components Ltd

Valve Train Components Ltd (VTC) is one of the leading suppliers of valve collets and synchromesh sliding keys to the global automotive market. A first tier supplier to many of the world’s premier automotive companies, it manufactures over 300 million valve collets per annum and exports to more than 20 countries...

Factors influencing your factory choice of CNC equipment (Part 2)

Besides the material, the type and the intended use of the CNC machine also play an important role in helping manufacturers choose the right equipment for their production model. Today, CNC machine models are constantly changing to meet market demand. The new generation CNC machines are mainly divided into 3-axis or...

Factors influencing your factory choice of CNC equipment (Part 2)

Besides the material, the type and the intended use of the CNC machine also play an important role in helping manufacturers choose the right equipment for their production model. Today, CNC machine models are constantly changing to meet market demand. The new generation CNC machines are mainly divided into 3-axis or...

Leyland Trucks successfully applying Lean manufacturing

Leyland Trucks manufactures the full range of DAF Trucks, from 7.5 to 44 tonnes, at its facility in Leyland. All vehicles are produced on one line at a rate of 20,000 per year. The facility operates in line with the Paccar Production System (PPS) and Leyland Trucks is one of the...

Leyland Trucks successfully applying Lean manufacturing

Leyland Trucks manufactures the full range of DAF Trucks, from 7.5 to 44 tonnes, at its facility in Leyland. All vehicles are produced on one line at a rate of 20,000 per year. The facility operates in line with the Paccar Production System (PPS) and Leyland Trucks is one of the...

MRT Castings: Promote technological innovation and management system adoption (Part 2)

One of the outstanding technology applications that has helped MRT Castings significantly improve productivity and product quality is Brother’s Speedio M140X2. With the Speedio M140X2, raw materials entering the new Brother machine are fed automatically from the Feedio robot handling system, including the casting and the workpiece being fed into the...

MRT Castings: Promote technological innovation and management system adoption (Part 2)

One of the outstanding technology applications that has helped MRT Castings significantly improve productivity and product quality is Brother’s Speedio M140X2. With the Speedio M140X2, raw materials entering the new Brother machine are fed automatically from the Feedio robot handling system, including the casting and the workpiece being fed into the...

MRT Castings: Promoting technological innovation and management system adoption (Part 1)

MRT Castings is a long-established UK-based company specializing in gravity casting and machine building, with over 70 years of industry experience. Currently the company’s products are present in many regions around the world such as North America, Western Europe, Central Asia, the Middle East and Africa, etc. With the aim of...

MRT Castings: Promoting technological innovation and management system adoption (Part 1)

MRT Castings is a long-established UK-based company specializing in gravity casting and machine building, with over 70 years of industry experience. Currently the company’s products are present in many regions around the world such as North America, Western Europe, Central Asia, the Middle East and Africa, etc. With the aim of...

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 3)

When it comes to the advantages of the Qwik-Lok vise clamps over traditional clamps, the Qwik-Lok’s short set-up time is arguably the most outstanding. In the past, standard wound rollers were used to fix machining parts on CNC machining machines and centers, but as the production intensity increased, these ethers gradually...

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 3)

When it comes to the advantages of the Qwik-Lok vise clamps over traditional clamps, the Qwik-Lok’s short set-up time is arguably the most outstanding. In the past, standard wound rollers were used to fix machining parts on CNC machining machines and centers, but as the production intensity increased, these ethers gradually...

VINGAL-VNSTEEL: Increasing competitiveness thanks to quality

Operating in the context of fierce competition market, VINGAL-VNSTEEL Industrial Galvanized Joint Stock Company has been continuously investing in technology and improving product quality to increase competitiveness. With a long tradition of over 24 years of construction and development, VINGAL-VNSTEEL Industrial Galvanized Joint Stock Company specializes in manufacturing and trading in...

VINGAL-VNSTEEL: Increasing competitiveness thanks to quality

Operating in the context of fierce competition market, VINGAL-VNSTEEL Industrial Galvanized Joint Stock Company has been continuously investing in technology and improving product quality to increase competitiveness. With a long tradition of over 24 years of construction and development, VINGAL-VNSTEEL Industrial Galvanized Joint Stock Company specializes in manufacturing and trading in...

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 2)

Not only has a flexible design, Hoffman’s Garant Xtric also has a lot of outstanding features. With double spring construction and linear clamping, the clamping force of the device can be up to 25 kN. The special tooth design of Garant Xtric helps to keep and clamp the products, even in...

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 2)

Not only has a flexible design, Hoffman’s Garant Xtric also has a lot of outstanding features. With double spring construction and linear clamping, the clamping force of the device can be up to 25 kN. The special tooth design of Garant Xtric helps to keep and clamp the products, even in...

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 1)

In the process of mechanical machining, the jigs to clamp the details, ensuring the machining stability are extremely important. Such clamping and clamping tools are called vents. Currently, many manufacturers are developing their own cars to help improve production capacity. A typical example is the Garant Xtric clamping device researched and...

Innovative automotive equipment: A cost-effective solution for the mechanical industry (Part 1)

In the process of mechanical machining, the jigs to clamp the details, ensuring the machining stability are extremely important. Such clamping and clamping tools are called vents. Currently, many manufacturers are developing their own cars to help improve production capacity. A typical example is the Garant Xtric clamping device researched and...

At the cutting edge of continuous improvement

1 million parts per month, from brackets to fully functioning coffee machines. An average batch size of just 36 parts and the introduction of 450 new parts per month. Yet the employees at this fast moving engineering firm still found time to save £435,000 last year. I went to catch up...

At the cutting edge of continuous improvement

1 million parts per month, from brackets to fully functioning coffee machines. An average batch size of just 36 parts and the introduction of 450 new parts per month. Yet the employees at this fast moving engineering firm still found time to save £435,000 last year. I went to catch up...