-

Using PCS tool to improve line speed

The production line was suffering from the lost output, high rework, and high waste at its assembly stations. Each assembly station had to pick one component from the delivery belt, re-orientate it, place it in the assembly carousel then pick a second component from the delivery belt and place it accurately...

Using PCS tool to improve line speed

The production line was suffering from the lost output, high rework, and high waste at its assembly stations. Each assembly station had to pick one component from the delivery belt, re-orientate it, place it in the assembly carousel then pick a second component from the delivery belt and place it accurately...

-

Kaizen and Japanese quality circle

Kaizen is a philosophical and systematic approach, developed by Japan after World War II. In Japanese, Kaizen is compounded from “Kai” – “change” or “get it right” and “Zen” – “good”, means “continuous improvement”. Kaizen is the accumulation of small improvements into big results, focusing on problem identification, problem solving and...

Kaizen and Japanese quality circle

Kaizen is a philosophical and systematic approach, developed by Japan after World War II. In Japanese, Kaizen is compounded from “Kai” – “change” or “get it right” and “Zen” – “good”, means “continuous improvement”. Kaizen is the accumulation of small improvements into big results, focusing on problem identification, problem solving and...

-

Principle of punctuality in the manufacturing plant

Discipline and punctuality are two principles that not only help each individual succeed in their work but also contribute significantly to the success of the team. Discipline ensures individuals behave according to a common workplace standard, and this also helps managers exploit the collective strength of their organizations. In some factory...

Principle of punctuality in the manufacturing plant

Discipline and punctuality are two principles that not only help each individual succeed in their work but also contribute significantly to the success of the team. Discipline ensures individuals behave according to a common workplace standard, and this also helps managers exploit the collective strength of their organizations. In some factory...

-

MFG Chemical Renews ISO 9001: 2015 Certification Of Three Dalton, GA Plants

MFG Chemical, a global leader in specialty and custom chemical manufacturing has successfully renewed its ISO 9001:2015 Certifications at each of its three Dalton, Georgia facilities (Certification of Pasadena, TX Plant Planned for 2020). MFG was one of the first chemical companies to achieve ISO 9001: 2015 certification in October of...

MFG Chemical Renews ISO 9001: 2015 Certification Of Three Dalton, GA Plants

MFG Chemical, a global leader in specialty and custom chemical manufacturing has successfully renewed its ISO 9001:2015 Certifications at each of its three Dalton, Georgia facilities (Certification of Pasadena, TX Plant Planned for 2020). MFG was one of the first chemical companies to achieve ISO 9001: 2015 certification in October of...

-

ISO 2800: Supply chain management systems for businesses

Upgrading from the technical standards to an international standard, the ISO 28000 set of security management systems for the supply chain will contribute to reducing risks for people and goods in the chain. supply. This set of standards addresses potential security issues at all stages of the supply process including threats...

ISO 2800: Supply chain management systems for businesses

Upgrading from the technical standards to an international standard, the ISO 28000 set of security management systems for the supply chain will contribute to reducing risks for people and goods in the chain. supply. This set of standards addresses potential security issues at all stages of the supply process including threats...

-

How Amada Miyachi America implemented the 6S system (Part 3)

In order to standardize the changes from the first 3S, AMYA organized exchange meetings to enable employees to share their difficulties with management to find a solution together. 6S posters have also been placed around the work area to remind employees of their commitment. AMYA has maintained its efforts to optimize...

How Amada Miyachi America implemented the 6S system (Part 3)

In order to standardize the changes from the first 3S, AMYA organized exchange meetings to enable employees to share their difficulties with management to find a solution together. 6S posters have also been placed around the work area to remind employees of their commitment. AMYA has maintained its efforts to optimize...

-

Benefits from applying management systems at Tata Global Beverages

Tata Global Beverages holds multiple standards, including ISO 9001 (Quality Management), ISO 14001 (Environmental Management), ISO 50001 (Energy Management) and BS OHSAS 18001 (Occupational Health and Safety). With the exception of ISO 9001, which was achieved 20 years ago, Denise Graham, the company’s Technical Manager, has overseen accreditation to all of...

Benefits from applying management systems at Tata Global Beverages

Tata Global Beverages holds multiple standards, including ISO 9001 (Quality Management), ISO 14001 (Environmental Management), ISO 50001 (Energy Management) and BS OHSAS 18001 (Occupational Health and Safety). With the exception of ISO 9001, which was achieved 20 years ago, Denise Graham, the company’s Technical Manager, has overseen accreditation to all of...

-

5 Ways to support continuous improvement in production with Real-Time Tracking (Part 3) ...

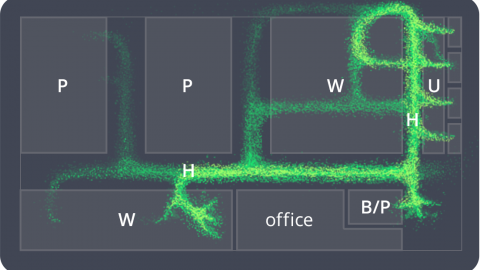

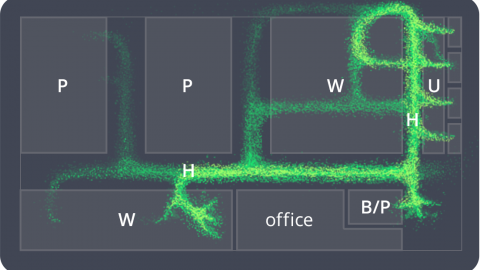

RTLS can help Kaizen in: 3. Maximize Asset Utilization There are many mobile assets involved in production and intralogistics processes such as forklifts, tugger trains, molds, AGV and primarily people. All of them require Capital expenditure (CapEx) and/or Operating Expenditure (OpEx). The costs quickly add up and are difficult to control...

5 Ways to support continuous improvement in production with Real-Time Tracking (Part 3) ...

RTLS can help Kaizen in: 3. Maximize Asset Utilization There are many mobile assets involved in production and intralogistics processes such as forklifts, tugger trains, molds, AGV and primarily people. All of them require Capital expenditure (CapEx) and/or Operating Expenditure (OpEx). The costs quickly add up and are difficult to control...

-

5 Ways to support continuous improvement in production with Real-Time Tracking (Part 2) ...

Based on our experience in implementing real-time tracking in production and internal logistics, data and insights collected by RTLS can support Kaizen in the following ways. 1. More Effective Inventory Management One of the cases we have come across was a manager of a factory that produces truck tires, who wanted...

5 Ways to support continuous improvement in production with Real-Time Tracking (Part 2) ...

Based on our experience in implementing real-time tracking in production and internal logistics, data and insights collected by RTLS can support Kaizen in the following ways. 1. More Effective Inventory Management One of the cases we have come across was a manager of a factory that produces truck tires, who wanted...

-

5 Ways to support continuous improvement in production with Real-Time Tracking (Part 1) ...

Manufacturers face constant pressure from clients to deliver better products. They want better quality, faster delivery, and lower prices. The common way to address these demands is to implement a Continuous Improvement (Kaizen) approach to production processes. However, an even better way is to implement Kaizen together with new Industry 4.0...

5 Ways to support continuous improvement in production with Real-Time Tracking (Part 1) ...

Manufacturers face constant pressure from clients to deliver better products. They want better quality, faster delivery, and lower prices. The common way to address these demands is to implement a Continuous Improvement (Kaizen) approach to production processes. However, an even better way is to implement Kaizen together with new Industry 4.0...

Scroll

Using PCS tool to improve line speed

The production line was suffering from the lost output, high rework, and high waste at its assembly stations. Each assembly station had to pick one component from the delivery belt, re-orientate it, place it in the assembly carousel then pick a second component from the delivery belt and place it accurately...

Using PCS tool to improve line speed

The production line was suffering from the lost output, high rework, and high waste at its assembly stations. Each assembly station had to pick one component from the delivery belt, re-orientate it, place it in the assembly carousel then pick a second component from the delivery belt and place it accurately...

Kaizen and Japanese quality circle

Kaizen is a philosophical and systematic approach, developed by Japan after World War II. In Japanese, Kaizen is compounded from “Kai” – “change” or “get it right” and “Zen” – “good”, means “continuous improvement”. Kaizen is the accumulation of small improvements into big results, focusing on problem identification, problem solving and...

Kaizen and Japanese quality circle

Kaizen is a philosophical and systematic approach, developed by Japan after World War II. In Japanese, Kaizen is compounded from “Kai” – “change” or “get it right” and “Zen” – “good”, means “continuous improvement”. Kaizen is the accumulation of small improvements into big results, focusing on problem identification, problem solving and...

Principle of punctuality in the manufacturing plant

Discipline and punctuality are two principles that not only help each individual succeed in their work but also contribute significantly to the success of the team. Discipline ensures individuals behave according to a common workplace standard, and this also helps managers exploit the collective strength of their organizations. In some factory...

Principle of punctuality in the manufacturing plant

Discipline and punctuality are two principles that not only help each individual succeed in their work but also contribute significantly to the success of the team. Discipline ensures individuals behave according to a common workplace standard, and this also helps managers exploit the collective strength of their organizations. In some factory...

MFG Chemical Renews ISO 9001: 2015 Certification Of Three Dalton, GA Plants

MFG Chemical, a global leader in specialty and custom chemical manufacturing has successfully renewed its ISO 9001:2015 Certifications at each of its three Dalton, Georgia facilities (Certification of Pasadena, TX Plant Planned for 2020). MFG was one of the first chemical companies to achieve ISO 9001: 2015 certification in October of...

MFG Chemical Renews ISO 9001: 2015 Certification Of Three Dalton, GA Plants

MFG Chemical, a global leader in specialty and custom chemical manufacturing has successfully renewed its ISO 9001:2015 Certifications at each of its three Dalton, Georgia facilities (Certification of Pasadena, TX Plant Planned for 2020). MFG was one of the first chemical companies to achieve ISO 9001: 2015 certification in October of...

ISO 2800: Supply chain management systems for businesses

Upgrading from the technical standards to an international standard, the ISO 28000 set of security management systems for the supply chain will contribute to reducing risks for people and goods in the chain. supply. This set of standards addresses potential security issues at all stages of the supply process including threats...

ISO 2800: Supply chain management systems for businesses

Upgrading from the technical standards to an international standard, the ISO 28000 set of security management systems for the supply chain will contribute to reducing risks for people and goods in the chain. supply. This set of standards addresses potential security issues at all stages of the supply process including threats...

How Amada Miyachi America implemented the 6S system (Part 3)

In order to standardize the changes from the first 3S, AMYA organized exchange meetings to enable employees to share their difficulties with management to find a solution together. 6S posters have also been placed around the work area to remind employees of their commitment. AMYA has maintained its efforts to optimize...

How Amada Miyachi America implemented the 6S system (Part 3)

In order to standardize the changes from the first 3S, AMYA organized exchange meetings to enable employees to share their difficulties with management to find a solution together. 6S posters have also been placed around the work area to remind employees of their commitment. AMYA has maintained its efforts to optimize...

Benefits from applying management systems at Tata Global Beverages

Tata Global Beverages holds multiple standards, including ISO 9001 (Quality Management), ISO 14001 (Environmental Management), ISO 50001 (Energy Management) and BS OHSAS 18001 (Occupational Health and Safety). With the exception of ISO 9001, which was achieved 20 years ago, Denise Graham, the company’s Technical Manager, has overseen accreditation to all of...

Benefits from applying management systems at Tata Global Beverages

Tata Global Beverages holds multiple standards, including ISO 9001 (Quality Management), ISO 14001 (Environmental Management), ISO 50001 (Energy Management) and BS OHSAS 18001 (Occupational Health and Safety). With the exception of ISO 9001, which was achieved 20 years ago, Denise Graham, the company’s Technical Manager, has overseen accreditation to all of...

5 Ways to support continuous improvement in production with Real-Time Tracking (Part 3) ...

RTLS can help Kaizen in: 3. Maximize Asset Utilization There are many mobile assets involved in production and intralogistics processes such as forklifts, tugger trains, molds, AGV and primarily people. All of them require Capital expenditure (CapEx) and/or Operating Expenditure (OpEx). The costs quickly add up and are difficult to control...

5 Ways to support continuous improvement in production with Real-Time Tracking (Part 3) ...

RTLS can help Kaizen in: 3. Maximize Asset Utilization There are many mobile assets involved in production and intralogistics processes such as forklifts, tugger trains, molds, AGV and primarily people. All of them require Capital expenditure (CapEx) and/or Operating Expenditure (OpEx). The costs quickly add up and are difficult to control...

5 Ways to support continuous improvement in production with Real-Time Tracking (Part 2) ...

Based on our experience in implementing real-time tracking in production and internal logistics, data and insights collected by RTLS can support Kaizen in the following ways. 1. More Effective Inventory Management One of the cases we have come across was a manager of a factory that produces truck tires, who wanted...

5 Ways to support continuous improvement in production with Real-Time Tracking (Part 2) ...

Based on our experience in implementing real-time tracking in production and internal logistics, data and insights collected by RTLS can support Kaizen in the following ways. 1. More Effective Inventory Management One of the cases we have come across was a manager of a factory that produces truck tires, who wanted...

5 Ways to support continuous improvement in production with Real-Time Tracking (Part 1) ...

Manufacturers face constant pressure from clients to deliver better products. They want better quality, faster delivery, and lower prices. The common way to address these demands is to implement a Continuous Improvement (Kaizen) approach to production processes. However, an even better way is to implement Kaizen together with new Industry 4.0...

5 Ways to support continuous improvement in production with Real-Time Tracking (Part 1) ...

Manufacturers face constant pressure from clients to deliver better products. They want better quality, faster delivery, and lower prices. The common way to address these demands is to implement a Continuous Improvement (Kaizen) approach to production processes. However, an even better way is to implement Kaizen together with new Industry 4.0...