-

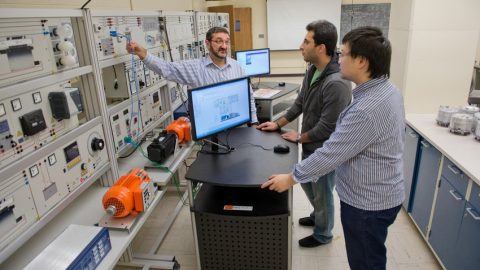

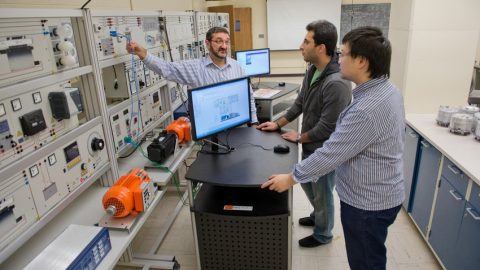

Artificial Intelligence and Machine Learning improve manufacturing productivity

Engineers at the Advanced Manufacturing Research Centre’s Factory 2050 in Sheffield, UK are using Artificial Intelligence (AI) to learn what machine utilization looks like on the workshop floor. The aim is to create a demonstrator to show just how accessible Industry 4.0 technologies are, and how they can potentially revolutionize shop-floor...

Artificial Intelligence and Machine Learning improve manufacturing productivity

Engineers at the Advanced Manufacturing Research Centre’s Factory 2050 in Sheffield, UK are using Artificial Intelligence (AI) to learn what machine utilization looks like on the workshop floor. The aim is to create a demonstrator to show just how accessible Industry 4.0 technologies are, and how they can potentially revolutionize shop-floor...

-

Introducion of lean management systems integrating technology 4.0 (Part 2)

The 10 key elements of a lean manufacturing system are divided into four groups including suppliers, processes, customers and control parties. Each group has its own potential to integrate the advantages of technology 4.0. Supplier factors The robustness of information exchanges among customers, manufacturers or process owners, and suppliers determines the...

Introducion of lean management systems integrating technology 4.0 (Part 2)

The 10 key elements of a lean manufacturing system are divided into four groups including suppliers, processes, customers and control parties. Each group has its own potential to integrate the advantages of technology 4.0. Supplier factors The robustness of information exchanges among customers, manufacturers or process owners, and suppliers determines the...

-

Introducion of lean management systems integrating technology 4.0 (Part 1)

Combining lean with Industry 4.0 can lead to new manufacturing horizons. Over the years, lean manufacturing systems have become widely used by many companies as a fundamental methodology to increase productivity and reduce nonvalue-added waste. However, nowadays, when the principles of lean production are rooted in the spirit of many companies,...

Introducion of lean management systems integrating technology 4.0 (Part 1)

Combining lean with Industry 4.0 can lead to new manufacturing horizons. Over the years, lean manufacturing systems have become widely used by many companies as a fundamental methodology to increase productivity and reduce nonvalue-added waste. However, nowadays, when the principles of lean production are rooted in the spirit of many companies,...

-

The conversion of the Spanish metallurgical sector to industry 4.0 would increase its ...

The Spanish metal sector is made up of a total of 62,471 companies that carry out their activity in various subsectors, ranging from foundry and transformation activities to the manufacture of all types of metal products, through the construction of machinery and mechanical equipment and the manufacture of electronic equipment. The...

The conversion of the Spanish metallurgical sector to industry 4.0 would increase its ...

The Spanish metal sector is made up of a total of 62,471 companies that carry out their activity in various subsectors, ranging from foundry and transformation activities to the manufacture of all types of metal products, through the construction of machinery and mechanical equipment and the manufacture of electronic equipment. The...

-

11 Inspiring Case Studies Of Digital Transformation (Part 3)

In this section, we will continue with the successful digital transformation models of some famous brands in the world such as MCDONAL, Netspresso, Starbuck and Under Armor: MCDONALD’S: Recognized a massive shift in consumer behavior. For example, in 2015, McDonald’s began installing kiosks where customers can quickly customize their hamburgers. One...

11 Inspiring Case Studies Of Digital Transformation (Part 3)

In this section, we will continue with the successful digital transformation models of some famous brands in the world such as MCDONAL, Netspresso, Starbuck and Under Armor: MCDONALD’S: Recognized a massive shift in consumer behavior. For example, in 2015, McDonald’s began installing kiosks where customers can quickly customize their hamburgers. One...

-

11 Inspiring Case Studies Of Digital Transformation (Part 2)

In this section, we will continue with the successful digital transformation models of some famous brands in the world such as General Electric, Glass Door, LEGO and MCCORMICK: GENERAL ELECTRIC: GE’s Digital Wind Farm is an adaptable wind energy ecosystem that pairs turbines with the digital infrastructure for the wind energy...

11 Inspiring Case Studies Of Digital Transformation (Part 2)

In this section, we will continue with the successful digital transformation models of some famous brands in the world such as General Electric, Glass Door, LEGO and MCCORMICK: GENERAL ELECTRIC: GE’s Digital Wind Farm is an adaptable wind energy ecosystem that pairs turbines with the digital infrastructure for the wind energy...

-

10 things will change the way you approach TPM training (Part 2)

In this section, we will continue to explore other benefits of TPM training for employees. Perfection TPM is majorly applied for achieving machine perfection. In addition to machine availability other factors such as logistical and human aspects play an important role. That’s why the contribution of employees across different disciplines forms...

10 things will change the way you approach TPM training (Part 2)

In this section, we will continue to explore other benefits of TPM training for employees. Perfection TPM is majorly applied for achieving machine perfection. In addition to machine availability other factors such as logistical and human aspects play an important role. That’s why the contribution of employees across different disciplines forms...

-

11 Inspiring Case Studies Of Digital Transformation (Part 1)

Nowaday, many companies report they are undergoing digital transformation even though most don’t know how to go about it. Digital transformation is profound change in business activities, processes, competencies, and models to fully leverage customers at every touchpoint in the customer experience. Successful digital transformation achieve these results: CUSTOMER: Harness customer...

11 Inspiring Case Studies Of Digital Transformation (Part 1)

Nowaday, many companies report they are undergoing digital transformation even though most don’t know how to go about it. Digital transformation is profound change in business activities, processes, competencies, and models to fully leverage customers at every touchpoint in the customer experience. Successful digital transformation achieve these results: CUSTOMER: Harness customer...

-

ASQ Survey: Increase income by participating in quality training in the United States ...

The survey published annually by the American Quality Association (ASQ) found that employees’ salaries increased significantly after completing quality and quality improvement courses. The main findings were that learning quality and process improvement methodologies can boost careers in the most tangible way possible: higher salary potential. It also shows the potential...

ASQ Survey: Increase income by participating in quality training in the United States ...

The survey published annually by the American Quality Association (ASQ) found that employees’ salaries increased significantly after completing quality and quality improvement courses. The main findings were that learning quality and process improvement methodologies can boost careers in the most tangible way possible: higher salary potential. It also shows the potential...

-

10 things will change the way you approach TPM training (Part 1)

TPM training is the training to understand how the system (TPM) basically works and enhance the productivity, basically teaching how to minimize the waste in all phases of operations. Benefits of TPM Training Less unplanned maintenance time TPM revolves around employee empowerment and inspires employees to take ownership of their machinery...

10 things will change the way you approach TPM training (Part 1)

TPM training is the training to understand how the system (TPM) basically works and enhance the productivity, basically teaching how to minimize the waste in all phases of operations. Benefits of TPM Training Less unplanned maintenance time TPM revolves around employee empowerment and inspires employees to take ownership of their machinery...

Scroll

Artificial Intelligence and Machine Learning improve manufacturing productivity

Engineers at the Advanced Manufacturing Research Centre’s Factory 2050 in Sheffield, UK are using Artificial Intelligence (AI) to learn what machine utilization looks like on the workshop floor. The aim is to create a demonstrator to show just how accessible Industry 4.0 technologies are, and how they can potentially revolutionize shop-floor...

Artificial Intelligence and Machine Learning improve manufacturing productivity

Engineers at the Advanced Manufacturing Research Centre’s Factory 2050 in Sheffield, UK are using Artificial Intelligence (AI) to learn what machine utilization looks like on the workshop floor. The aim is to create a demonstrator to show just how accessible Industry 4.0 technologies are, and how they can potentially revolutionize shop-floor...

Introducion of lean management systems integrating technology 4.0 (Part 2)

The 10 key elements of a lean manufacturing system are divided into four groups including suppliers, processes, customers and control parties. Each group has its own potential to integrate the advantages of technology 4.0. Supplier factors The robustness of information exchanges among customers, manufacturers or process owners, and suppliers determines the...

Introducion of lean management systems integrating technology 4.0 (Part 2)

The 10 key elements of a lean manufacturing system are divided into four groups including suppliers, processes, customers and control parties. Each group has its own potential to integrate the advantages of technology 4.0. Supplier factors The robustness of information exchanges among customers, manufacturers or process owners, and suppliers determines the...

Introducion of lean management systems integrating technology 4.0 (Part 1)

Combining lean with Industry 4.0 can lead to new manufacturing horizons. Over the years, lean manufacturing systems have become widely used by many companies as a fundamental methodology to increase productivity and reduce nonvalue-added waste. However, nowadays, when the principles of lean production are rooted in the spirit of many companies,...

Introducion of lean management systems integrating technology 4.0 (Part 1)

Combining lean with Industry 4.0 can lead to new manufacturing horizons. Over the years, lean manufacturing systems have become widely used by many companies as a fundamental methodology to increase productivity and reduce nonvalue-added waste. However, nowadays, when the principles of lean production are rooted in the spirit of many companies,...

The conversion of the Spanish metallurgical sector to industry 4.0 would increase its ...

The Spanish metal sector is made up of a total of 62,471 companies that carry out their activity in various subsectors, ranging from foundry and transformation activities to the manufacture of all types of metal products, through the construction of machinery and mechanical equipment and the manufacture of electronic equipment. The...

The conversion of the Spanish metallurgical sector to industry 4.0 would increase its ...

The Spanish metal sector is made up of a total of 62,471 companies that carry out their activity in various subsectors, ranging from foundry and transformation activities to the manufacture of all types of metal products, through the construction of machinery and mechanical equipment and the manufacture of electronic equipment. The...

11 Inspiring Case Studies Of Digital Transformation (Part 3)

In this section, we will continue with the successful digital transformation models of some famous brands in the world such as MCDONAL, Netspresso, Starbuck and Under Armor: MCDONALD’S: Recognized a massive shift in consumer behavior. For example, in 2015, McDonald’s began installing kiosks where customers can quickly customize their hamburgers. One...

11 Inspiring Case Studies Of Digital Transformation (Part 3)

In this section, we will continue with the successful digital transformation models of some famous brands in the world such as MCDONAL, Netspresso, Starbuck and Under Armor: MCDONALD’S: Recognized a massive shift in consumer behavior. For example, in 2015, McDonald’s began installing kiosks where customers can quickly customize their hamburgers. One...

11 Inspiring Case Studies Of Digital Transformation (Part 2)

In this section, we will continue with the successful digital transformation models of some famous brands in the world such as General Electric, Glass Door, LEGO and MCCORMICK: GENERAL ELECTRIC: GE’s Digital Wind Farm is an adaptable wind energy ecosystem that pairs turbines with the digital infrastructure for the wind energy...

11 Inspiring Case Studies Of Digital Transformation (Part 2)

In this section, we will continue with the successful digital transformation models of some famous brands in the world such as General Electric, Glass Door, LEGO and MCCORMICK: GENERAL ELECTRIC: GE’s Digital Wind Farm is an adaptable wind energy ecosystem that pairs turbines with the digital infrastructure for the wind energy...

10 things will change the way you approach TPM training (Part 2)

In this section, we will continue to explore other benefits of TPM training for employees. Perfection TPM is majorly applied for achieving machine perfection. In addition to machine availability other factors such as logistical and human aspects play an important role. That’s why the contribution of employees across different disciplines forms...

10 things will change the way you approach TPM training (Part 2)

In this section, we will continue to explore other benefits of TPM training for employees. Perfection TPM is majorly applied for achieving machine perfection. In addition to machine availability other factors such as logistical and human aspects play an important role. That’s why the contribution of employees across different disciplines forms...

11 Inspiring Case Studies Of Digital Transformation (Part 1)

Nowaday, many companies report they are undergoing digital transformation even though most don’t know how to go about it. Digital transformation is profound change in business activities, processes, competencies, and models to fully leverage customers at every touchpoint in the customer experience. Successful digital transformation achieve these results: CUSTOMER: Harness customer...

11 Inspiring Case Studies Of Digital Transformation (Part 1)

Nowaday, many companies report they are undergoing digital transformation even though most don’t know how to go about it. Digital transformation is profound change in business activities, processes, competencies, and models to fully leverage customers at every touchpoint in the customer experience. Successful digital transformation achieve these results: CUSTOMER: Harness customer...

ASQ Survey: Increase income by participating in quality training in the United States ...

The survey published annually by the American Quality Association (ASQ) found that employees’ salaries increased significantly after completing quality and quality improvement courses. The main findings were that learning quality and process improvement methodologies can boost careers in the most tangible way possible: higher salary potential. It also shows the potential...

ASQ Survey: Increase income by participating in quality training in the United States ...

The survey published annually by the American Quality Association (ASQ) found that employees’ salaries increased significantly after completing quality and quality improvement courses. The main findings were that learning quality and process improvement methodologies can boost careers in the most tangible way possible: higher salary potential. It also shows the potential...

10 things will change the way you approach TPM training (Part 1)

TPM training is the training to understand how the system (TPM) basically works and enhance the productivity, basically teaching how to minimize the waste in all phases of operations. Benefits of TPM Training Less unplanned maintenance time TPM revolves around employee empowerment and inspires employees to take ownership of their machinery...

10 things will change the way you approach TPM training (Part 1)

TPM training is the training to understand how the system (TPM) basically works and enhance the productivity, basically teaching how to minimize the waste in all phases of operations. Benefits of TPM Training Less unplanned maintenance time TPM revolves around employee empowerment and inspires employees to take ownership of their machinery...