-

Jabil Improves Production Yield With Manufacturing Apps

Building complex assemblies is now a standard practice for electronic manufacturing services (EMS) companies. This reality applies to firms that do work locally, nationally or internationally. Jabil Inc. is a U.S.-based global EMS company with electronics design, supply chain, production and product management capabilities. It currently operates 90 plants in 23...

Jabil Improves Production Yield With Manufacturing Apps

Building complex assemblies is now a standard practice for electronic manufacturing services (EMS) companies. This reality applies to firms that do work locally, nationally or internationally. Jabil Inc. is a U.S.-based global EMS company with electronics design, supply chain, production and product management capabilities. It currently operates 90 plants in 23...

-

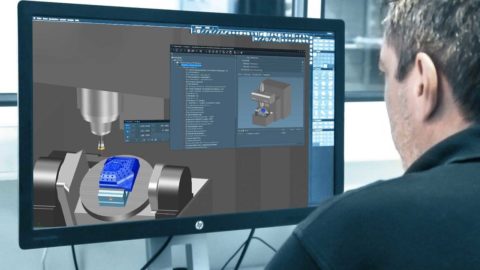

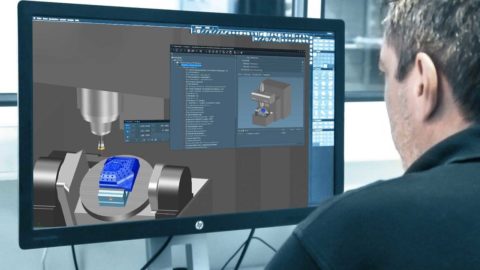

Smart manufacturing at APH3G thanks to CAD/CAM technology (Part 1)

APH3G Company was formerly Arthur Pollard Hollings, a manufacturer with 60 years of experience in the field of vacuum casting, fiberglass mold manufacturing, machining, prototype assembly and equipment fixtures, machine parts. To solve the problem of inventory due to errors, APH3G decided to invest in an intelligent production line with high...

Smart manufacturing at APH3G thanks to CAD/CAM technology (Part 1)

APH3G Company was formerly Arthur Pollard Hollings, a manufacturer with 60 years of experience in the field of vacuum casting, fiberglass mold manufacturing, machining, prototype assembly and equipment fixtures, machine parts. To solve the problem of inventory due to errors, APH3G decided to invest in an intelligent production line with high...

-

Injection Moulded Trim Parts: A case study in value stream transformation

The client is one of the world’s largest suppliers of automotive interior components who supply all of the major automotive OEMs. Their core product categories include door and trim systems, instrument panels, consoles, cockpits, flooring, acoustic systems, headliner and overhead systems as well as complementary exterior components. To meet all of...

Injection Moulded Trim Parts: A case study in value stream transformation

The client is one of the world’s largest suppliers of automotive interior components who supply all of the major automotive OEMs. Their core product categories include door and trim systems, instrument panels, consoles, cockpits, flooring, acoustic systems, headliner and overhead systems as well as complementary exterior components. To meet all of...

-

BM Injection: Renovating equipment to improve production capacity (Part 2)

Since the inception of use Makino D200Z has shown that the investment of BM Injection is completely worth it. Machining is now more convenient than ever with the D200Z’s custom memorization and input machining data. Accordingly, the operator only needs one activation operation instead of 2-3 as before (Including setting the...

BM Injection: Renovating equipment to improve production capacity (Part 2)

Since the inception of use Makino D200Z has shown that the investment of BM Injection is completely worth it. Machining is now more convenient than ever with the D200Z’s custom memorization and input machining data. Accordingly, the operator only needs one activation operation instead of 2-3 as before (Including setting the...

-

BM Injection: Renovating equipment to improve production capacity (Part 1)

BM Injection is an experienced and specialized supplier of plastic products in the UK. Recently, the company has invested in renovating a number of factory equipment in preparation for an automation plan with the aim of improving overall equipment productivity. For tool steel machining process, until recently, BM Injection was still...

BM Injection: Renovating equipment to improve production capacity (Part 1)

BM Injection is an experienced and specialized supplier of plastic products in the UK. Recently, the company has invested in renovating a number of factory equipment in preparation for an automation plan with the aim of improving overall equipment productivity. For tool steel machining process, until recently, BM Injection was still...

-

Philips Lighting applies TPM to reduce waste

Philips (Uden) produces and delivers ceramic light components to internal Philips customers. The products go into two main Philips products, SON and MASTERColour lamps. These products are widely used in street lighting in greenhouses, for lighting of buildings and for lighting shops, showrooms, hotels and public spaces. Both discharge lamps have...

Philips Lighting applies TPM to reduce waste

Philips (Uden) produces and delivers ceramic light components to internal Philips customers. The products go into two main Philips products, SON and MASTERColour lamps. These products are widely used in street lighting in greenhouses, for lighting of buildings and for lighting shops, showrooms, hotels and public spaces. Both discharge lamps have...

-

Dominance of the digital twins in the race for technology

Manufacturers are changing day by day to keep pace with increasingly demanding customer requirements, and one of the potential solutions is technological innovation. In the race for technology, the concept of the Digital Twins integrating the Internet of Things in Industry (IIoT) is a prominent trend today. Digital twins can be...

Dominance of the digital twins in the race for technology

Manufacturers are changing day by day to keep pace with increasingly demanding customer requirements, and one of the potential solutions is technological innovation. In the race for technology, the concept of the Digital Twins integrating the Internet of Things in Industry (IIoT) is a prominent trend today. Digital twins can be...

-

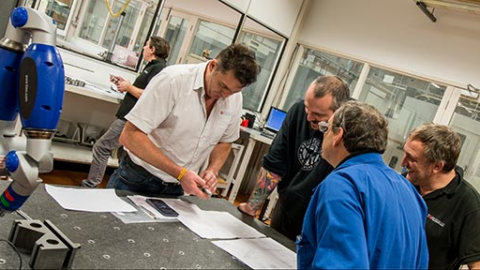

Experience of successfully applying TPM at Valvetrain Components Ltd

Valve Train Components Ltd (VTC) is one of the leading suppliers of valve collets and synchromesh sliding keys to the global automotive market. A first tier supplier to many of the world’s premier automotive companies, it manufactures over 300 million valve collets per annum and exports to more than 20 countries...

Experience of successfully applying TPM at Valvetrain Components Ltd

Valve Train Components Ltd (VTC) is one of the leading suppliers of valve collets and synchromesh sliding keys to the global automotive market. A first tier supplier to many of the world’s premier automotive companies, it manufactures over 300 million valve collets per annum and exports to more than 20 countries...

-

Factors influencing your factory choice of CNC equipment (Part 2)

Besides the material, the type and the intended use of the CNC machine also play an important role in helping manufacturers choose the right equipment for their production model. Today, CNC machine models are constantly changing to meet market demand. The new generation CNC machines are mainly divided into 3-axis or...

Factors influencing your factory choice of CNC equipment (Part 2)

Besides the material, the type and the intended use of the CNC machine also play an important role in helping manufacturers choose the right equipment for their production model. Today, CNC machine models are constantly changing to meet market demand. The new generation CNC machines are mainly divided into 3-axis or...

-

T & R Precision focuses on applying technology to improve quality (Part 1) ...

T & R Precision is a mechanical machining services company based in Foulridge, East Lancashire, UK. With extensive industry experience and highly qualified staff, T & R Precision has become one of the few regional manufacturers and processors capable of supplying precision mechanical components for the aerospace industry. In the field...

T & R Precision focuses on applying technology to improve quality (Part 1) ...

T & R Precision is a mechanical machining services company based in Foulridge, East Lancashire, UK. With extensive industry experience and highly qualified staff, T & R Precision has become one of the few regional manufacturers and processors capable of supplying precision mechanical components for the aerospace industry. In the field...

Scroll

Jabil Improves Production Yield With Manufacturing Apps

Building complex assemblies is now a standard practice for electronic manufacturing services (EMS) companies. This reality applies to firms that do work locally, nationally or internationally. Jabil Inc. is a U.S.-based global EMS company with electronics design, supply chain, production and product management capabilities. It currently operates 90 plants in 23...

Jabil Improves Production Yield With Manufacturing Apps

Building complex assemblies is now a standard practice for electronic manufacturing services (EMS) companies. This reality applies to firms that do work locally, nationally or internationally. Jabil Inc. is a U.S.-based global EMS company with electronics design, supply chain, production and product management capabilities. It currently operates 90 plants in 23...

Smart manufacturing at APH3G thanks to CAD/CAM technology (Part 1)

APH3G Company was formerly Arthur Pollard Hollings, a manufacturer with 60 years of experience in the field of vacuum casting, fiberglass mold manufacturing, machining, prototype assembly and equipment fixtures, machine parts. To solve the problem of inventory due to errors, APH3G decided to invest in an intelligent production line with high...

Smart manufacturing at APH3G thanks to CAD/CAM technology (Part 1)

APH3G Company was formerly Arthur Pollard Hollings, a manufacturer with 60 years of experience in the field of vacuum casting, fiberglass mold manufacturing, machining, prototype assembly and equipment fixtures, machine parts. To solve the problem of inventory due to errors, APH3G decided to invest in an intelligent production line with high...

Injection Moulded Trim Parts: A case study in value stream transformation

The client is one of the world’s largest suppliers of automotive interior components who supply all of the major automotive OEMs. Their core product categories include door and trim systems, instrument panels, consoles, cockpits, flooring, acoustic systems, headliner and overhead systems as well as complementary exterior components. To meet all of...

Injection Moulded Trim Parts: A case study in value stream transformation

The client is one of the world’s largest suppliers of automotive interior components who supply all of the major automotive OEMs. Their core product categories include door and trim systems, instrument panels, consoles, cockpits, flooring, acoustic systems, headliner and overhead systems as well as complementary exterior components. To meet all of...

BM Injection: Renovating equipment to improve production capacity (Part 2)

Since the inception of use Makino D200Z has shown that the investment of BM Injection is completely worth it. Machining is now more convenient than ever with the D200Z’s custom memorization and input machining data. Accordingly, the operator only needs one activation operation instead of 2-3 as before (Including setting the...

BM Injection: Renovating equipment to improve production capacity (Part 2)

Since the inception of use Makino D200Z has shown that the investment of BM Injection is completely worth it. Machining is now more convenient than ever with the D200Z’s custom memorization and input machining data. Accordingly, the operator only needs one activation operation instead of 2-3 as before (Including setting the...

BM Injection: Renovating equipment to improve production capacity (Part 1)

BM Injection is an experienced and specialized supplier of plastic products in the UK. Recently, the company has invested in renovating a number of factory equipment in preparation for an automation plan with the aim of improving overall equipment productivity. For tool steel machining process, until recently, BM Injection was still...

BM Injection: Renovating equipment to improve production capacity (Part 1)

BM Injection is an experienced and specialized supplier of plastic products in the UK. Recently, the company has invested in renovating a number of factory equipment in preparation for an automation plan with the aim of improving overall equipment productivity. For tool steel machining process, until recently, BM Injection was still...

Philips Lighting applies TPM to reduce waste

Philips (Uden) produces and delivers ceramic light components to internal Philips customers. The products go into two main Philips products, SON and MASTERColour lamps. These products are widely used in street lighting in greenhouses, for lighting of buildings and for lighting shops, showrooms, hotels and public spaces. Both discharge lamps have...

Philips Lighting applies TPM to reduce waste

Philips (Uden) produces and delivers ceramic light components to internal Philips customers. The products go into two main Philips products, SON and MASTERColour lamps. These products are widely used in street lighting in greenhouses, for lighting of buildings and for lighting shops, showrooms, hotels and public spaces. Both discharge lamps have...

Dominance of the digital twins in the race for technology

Manufacturers are changing day by day to keep pace with increasingly demanding customer requirements, and one of the potential solutions is technological innovation. In the race for technology, the concept of the Digital Twins integrating the Internet of Things in Industry (IIoT) is a prominent trend today. Digital twins can be...

Dominance of the digital twins in the race for technology

Manufacturers are changing day by day to keep pace with increasingly demanding customer requirements, and one of the potential solutions is technological innovation. In the race for technology, the concept of the Digital Twins integrating the Internet of Things in Industry (IIoT) is a prominent trend today. Digital twins can be...

Experience of successfully applying TPM at Valvetrain Components Ltd

Valve Train Components Ltd (VTC) is one of the leading suppliers of valve collets and synchromesh sliding keys to the global automotive market. A first tier supplier to many of the world’s premier automotive companies, it manufactures over 300 million valve collets per annum and exports to more than 20 countries...

Experience of successfully applying TPM at Valvetrain Components Ltd

Valve Train Components Ltd (VTC) is one of the leading suppliers of valve collets and synchromesh sliding keys to the global automotive market. A first tier supplier to many of the world’s premier automotive companies, it manufactures over 300 million valve collets per annum and exports to more than 20 countries...

Factors influencing your factory choice of CNC equipment (Part 2)

Besides the material, the type and the intended use of the CNC machine also play an important role in helping manufacturers choose the right equipment for their production model. Today, CNC machine models are constantly changing to meet market demand. The new generation CNC machines are mainly divided into 3-axis or...

Factors influencing your factory choice of CNC equipment (Part 2)

Besides the material, the type and the intended use of the CNC machine also play an important role in helping manufacturers choose the right equipment for their production model. Today, CNC machine models are constantly changing to meet market demand. The new generation CNC machines are mainly divided into 3-axis or...

T & R Precision focuses on applying technology to improve quality (Part 1) ...

T & R Precision is a mechanical machining services company based in Foulridge, East Lancashire, UK. With extensive industry experience and highly qualified staff, T & R Precision has become one of the few regional manufacturers and processors capable of supplying precision mechanical components for the aerospace industry. In the field...

T & R Precision focuses on applying technology to improve quality (Part 1) ...

T & R Precision is a mechanical machining services company based in Foulridge, East Lancashire, UK. With extensive industry experience and highly qualified staff, T & R Precision has become one of the few regional manufacturers and processors capable of supplying precision mechanical components for the aerospace industry. In the field...