Illustrator (Source: Internet)

A study that applied a TPM approach to innovation at a PTFE resin factory for 3 months was effective in increasing overall OEE equipment performance.

The main goal of the research is to improve the overall equipment efficiency (OEE) of each manufacturing process by improving the conditions of the equipment elements. OEE is defined as the percentage of the planned production time that is actually productive (Ade, 2014, p.7). OEE consists of three components, namely availability, performance and quality ratio. The OEE of each machine is a dependent variable describing the efficiency of each process, affected by 6 large losses (unplanned stop, setup and adjustment, small stop, low speed running, product failure and error due to boot).

TPM is a systematic approach that makes manufacturing processes more efficient by engaging everyone including operators, managers, and maintenance technicians. Researcher has adopted autonomous maintenance (AM) as the framework for this study. The research has given the manager of the PTFE unit a way to apply the TPM method in manufacturing.

Usually the application of self-governing maintenance pillars is performed through 7 main steps: Initial cleaning, eliminating sources of dirt and hard-to-reach areas, setting inspection and cleaning standards, advancing conduct equipment testing and training, conduct general process checks, systematize self-managed maintenance, and continually improve by self-managed maintenance. Because of the limited time, the researcher spent three months doing the study and the steps of AM implementation have been simplified. AM operations involve restoring to the condition of the equipment that has been replaced by selecting a machine with better conditions. After that, AM activities will be managed continuously in daily production.

The study includes the following phases:

1. Selection of machine and process

2. Evaluate the machine condition

3. Measure the machine’s base OEE

4. Train the machine operator

5. Perform AM on the selected machine

6. Measure OEE after performing AM

Machine and process selection: Researchers and managers have selected the best machines and processes based on a review of machine profiles, to see if all machine components are working properly in the Time ago no. There are three CNC machines from the CNC Workshop, one group from the Workshop, one group from the Model Workshop selected.

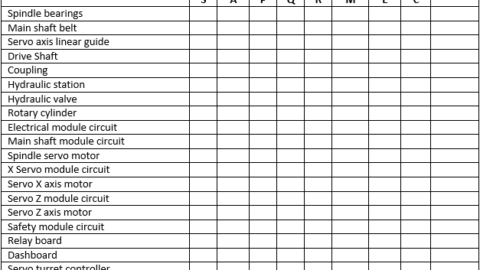

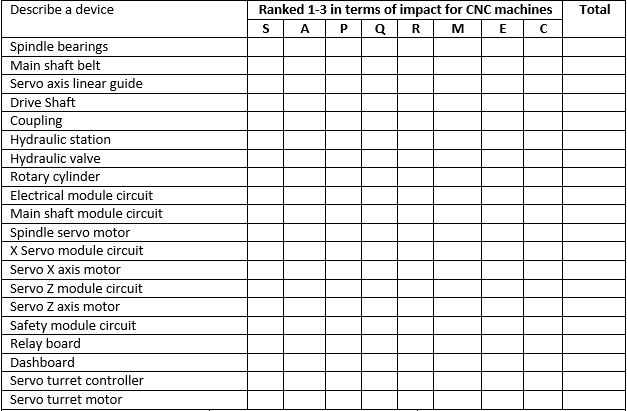

Machine condition assessment: Researcher and participant conduct equipment condition assessment using the form in Tables 1 and 2. The operator will clean and lubricate the equipment based on the condition ratings from the Table. 1 and 2.

Table 1: An example of the #1 CNC machine critical impact assessment matrix sample

Baseline OEE Measurement: In this step, the researcher selected three-month data from the previous year and computed the initial OEE of the selected machines. These data are compared with data after the self-managed maintenance was applied.

Operator training: During this stage, the researcher needs the cooperation of supervisors to establish the operator training schedule (see Table 3). In addition, a checklist titled “Daily cleaning and check-in checklist” was created to guide daily activities in cleaning and checking. Table 4 shows an example of hygiene inspection and daily inspection.

Instrumentation: In this study, the tools described previously assisted participants in applying TPM measures to PTFE plant processes.

1. Sample assessment matrix is important.

2. Evaluate the machine condition

3. Sample for daily inspection and supervision.

4. Self-managed maintenance training schedule (for operators).

Result: The OEE of CNC machine # 1 in 2016 before AM implementation was 82.7% and 2017 after implementation of AM was 83.8%. The increase is about 1.1%. Planned production time increased from 30,080 minutes to 30,225 minutes. The breakdown time in 2016 was 60 minutes, while it was 0 in 2017.

Setup time increased from 2,853 minutes to 2,926 minutes. Set-up time refers to the time the operator adjusts the machine’s running parameters to achieve the product quality standards. PF&D time (time for personal activities, fatigue and delays according to the US Department of Labor, 2008) was reduced from 665 minutes to 650 minutes. Running time increased from 26,502 minutes to 26,649 minutes. Total products increased from 100,956 units to 102,516 units. Defects decreased from 1,477 units to 1,255 units.

Source: Digitalcommon