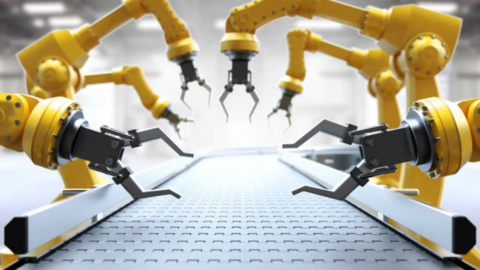

The Industrial Robots Association (RIA) has defined: “An industrial robot is a pre-programmed multifunction device that moves materials, parts, tools or some special equipment through a variety of programs. Various motion simulation software”.

These robots are described as a series of kinetic axes called links and connected by joints. Some models have a kinetic chain consisting of 4 axes. Typical industrial robots are mounted on a fixed base and connected to other links. The terminals are attached to the free-joint and allow the robot to manipulate objects to perform required tasks. With the development of artificial intelligence (AI), industrial robots are now more modern, smarter and adaptable to many different jobs.

Industry is getting smarter, and so are machines. Smart robots appear with the task of increasing efficiency at work in the office or factory while not using a lot of manpower. Different industrial manufacturers use different intelligent robots for their particular job.

It is worth noting that smart robots are a harmonious combination of motion simulation, sensing and automatic control, which is still being used by factories in their production lines to enhance quality. quality and competitiveness for products. Devices such as robots are designed to perform a wider range of tasks than conventional machines, from teaching in schools, to arc welding in the automotive industry, military weapons or space industry.

“Industrial robots will need to develop into intelligent, self-propelled machines with virtual brains that can make their own decisions”, said Juan Aparicio, Head of Advanced Manufacturing Automation at Siemen Technology Corporation. at the time of need. On the one hand, the era of low-cost foreign workers is coming to an end. On the other hand, due to the shortage of skilled workers in the developed countries, this makes it difficult for companies to reorganize. To enhance worker productivity and increase human-robot collaboration, we need machines that can perform more tasks, be more programmable, and can react to unexpected doubt situations”.

These are not the only changes Aparicio sees in the robotics industry. He also said the impact of increasing brands while prices are down. Cheaper robots also mean reduced accuracy and repeatability. Aparicio thinks that improving the power of computers and artificial intelligence for robot applications will be the answer to many remaining problems. “Nothing is free. Making up for these shortcomings with machines and AI will allow robots to penetrate more into the manufacturing process, especially for small and medium businesses.”

According to Aparicio, the demand for smart robots in many fields is increasing day by day. Robotic Operation System (Robotic Operation System) will become the vehicle for researchers to bring higher level artificial intelligence into their robot systems in the future.

Productivity and Quality Office