Mr. Tao has many initiatives that benefit the company hundreds of million VND / year

SD One Member Limited Company was a precursor to SD manufacturing facility, was established in 1989 in My Tho City, Tien Giang Province. After nearly 30 years operating in the toy manufacturing industry, the company has become one of the prestigious brands in the domestic and international markets.

In order to maintain the brand image and constantly bring customers better quality products, the company management always encourages workers to proactively propose innovative initiatives as well as improve their creative spirit in product design.

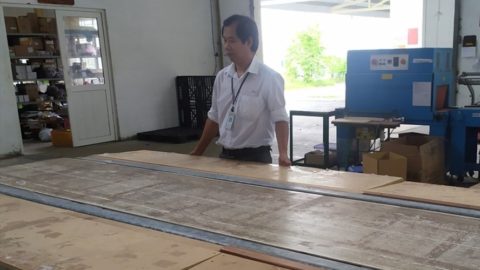

One of the typical examples of CD company improvement is Mr. Dao Tan Tao, an employee working directly in the technical department. Specifically, it is found that the process of toy products undergoes many stages, especially the assembly stage takes a lot of time and manpower. When doing this, the production department needs 10-12 workers to handle products placed in the center of the table. Although workers sit around doing their jobs, due to the large size of the table, it makes it difficult to reach for materials, the manipulation takes a lot of time and effort.

To solve this problem, Mr. Tao proposed to improve the assembly process by packing line. Accordingly, the conveyor system of raw materials and products is automatically moved to the working position of the workers, helping to operate quickly, reduce time and be more convenient.

Besides, the improvement helps reduce to 6 workers for the assembly process, saving labor costs about 300 million VND / year. Workers do not spend much time on getting raw materials, focus on assembling products faster, more evenly and more beautifully. Not only that, this packaging conveyor belt can operate continuously 24/24 to ensure work progress for all stages, freeing labor force of workers.

The product manufacturing process has a manual process, workers have to pull every part of the product, so there will be a difference in tightness or elasticity that is both laborious, reduced productivity but affects the quality. product quantity. Therefore, Mr. Tao has improved the process of manually changing pot linings to selling manually. With tools to assist in the operation, workers reduce labor, save time and at the same time, product quality is more uniform, meeting customer requirements. Increased labor efficiency, quality products, and delivery schedule have helped the Company get more orders and reach a turnover of about VND 200 million / year.

With Mr. Tao’s contributions, the Board of Directors and the Company’s Trade Union rewarded and honored him as a typical improvement example to promote proactive innovation at the company.

Productivity and Quality Office