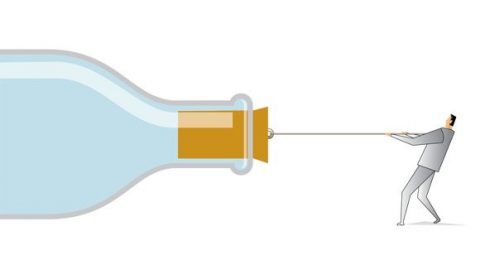

The elimination of “bottlenecks” is a systematic process but does not mean that all key decisions need to be discussed in depth. Stakeholders involved in the supply chain should have the freedom to make minor changes and upgrades whenever they need it (but there should be a good reason). Remember, bottlenecks can adversely affect decision making similar to its impact on supply chains.

Don’t rely on static models or diagrams to gain insight into something dynamic like the supply chain. Many smart tools aggregate data into static matrix sequences. That approach will fail to23 collapse the moving and changing elements in the supply chain. Focusing on the workflow (or not working) than focusing on key indicators will help companies identify more “bottlenecks” and will have more solutions.

Making long-term capital investment plans

The “bottleneck” bundle can cost a lot of money, and if the necessary funds can’t be met, the company may face many risks. Funds may be needed in the short, medium, and long term when making forecasts or dealing with investment issues. Tools such as “predictive analysis” can give companies a better view of their existence and give specific suggestions about the amount of money to spend in the future.

Thanks to the “predictive analysis” tool, engineers can answer tough questions such as “when is the best time to perform maintenance on some important equipment?” Applying static models and the data collected helps the company better understand its strengths and limitations. By doing so, they can directly improve their productivity or profitability.

Understand objectivity

Changing the supply chain to increase efficiency in a minimum or temporary manner is quite easy, but this is not the same as removing the “bottleneck”. Temporary solutions cannot identify the root of the problem, and the most noticeable result is that the “bottleneck” will return. In dealing with “bottlenecks”, people are often fooled by numbers. Be sure to focus on the really important objective factors.

Once the “bottleneck” is removed, the supply chain will be most effective. Because the supply chain operates smoothly rather than being affected by a “bottleneck,” engineers can begin to optimize the operation of the system. Conditions that exist for supply chains include their optimal operating state. Before that happens, all “bottlenecks” need to be permanently removed.

In today’s competitive economy, the supply chain plays an important role and brings certain advantages. Those companies that identify the “bottleneck” in their system and can eliminate it will gain a significant advantage in the market.

Productivity and Quality Office