Today, the investment cost for digital transformation for the global industry has reached US $ 1 trillion. Investments in modern technologies such as artificial intelligence (AI), machine learning hooks, big data (Bigdata), etc are skyrocketing thanks to the belief in the potential for improving quality and productivity dominance of the above technologies.

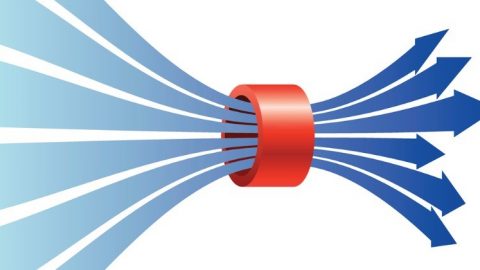

The applications of technology in the digital age are infinite. However, it also has to face one of the major hurdles that every business faces: Bottlenecks.

Occurs when a workload is poured in too quickly and beyond the processing power of subsequent steps to produce the expected result. As a result, the system stagnates and causes additional losses due to waste, the most noticeable is wastage due to waiting and redundant production processes that do not bring benefits to customers. Therefore, identifying, analyzing and removing bottlenecks is very important for businesses.

Predictive analysis is a prime example. By processing and coordinating operational data with information about machine performance, companies can now make predictions about events to come in the future. While not making the most accurate predictions, it provides these companies with a more accurate simulation model than the vague predictions companies often rely on.

Removing bottlenecks is easier said than done. The bottlenecks are sometimes not simply local in the position we see but we need to look over the entire operating system. Depending on the complexity of the knot, there are different methods for businesses. Enterprises rebuild the workflow system, it will be a lot easier to identify which ones work well and which ones appear malfunctioning.

The bottleneck effect can be caused by people, machines, processes or a combination of these factors. The cause of the bottleneck also determines its solution, identifying the cause of this phenomenon is the first step that must be taken. For humans, there is a need for training and supervision, whereas problems from machines and processes are often the ones that can be best overcome by automation and machine intelligence.

Small improvements can make a big impact. Taking Amazon as an example, they upgraded the program that could shorten a lot of time for truck drivers to check in at the center. The new process may save only a few tens of seconds for each vehicle, but it ensures the security of the gathering points and does not become an effect that makes the whole process at the center slow down.

It is worth noting that determining bottlenecks is a frequent or one-off problem. Some problems that occur in the supply chain can be very urgent, but once these issues are resolved, they will not happen again. For example, when a carrier arrives late, it is important to focus on how often it happens – for example, if this person is often late, it is a long-term problem.

Productivity and Quality Office