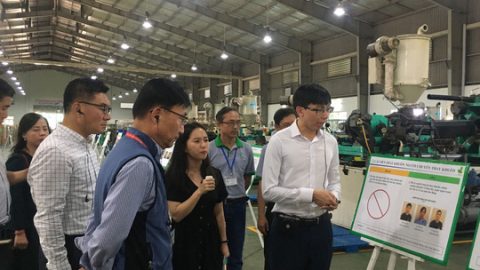

Samsung experts evaluate improvement results in Y Chi Viet Co., Ltd.

After 3 months of being consulted by Samsung Electric Vietnam Co., Ltd, 3 enterprises including Y Chi Viet Co., Ltd, TBM-Minh Phat Production and Trading Co., Ltd. and Viettronics and Mechanics Phu Tho Hoa JSC (VIEMCO) have changed positively in the production reform and their mindset.

Handle productivity and quality errors

The TBM-Minh Phat Production and Trading Company minimizes inventory from over 13 billion dong to 9 billion dong, shortening the mold replacement time from 30 minutes to 5-6 minutes. Y Chi Viet Co.,Ltd. improves over 100 items, rationalizing many production stages and manipulation, reducing the rate of failure.

For VIEMCO, Mr. Nguyen Duc Minh, Director of VIEMCO said “We improved nearly 70 items. The situation of the factory before improvement is much lower than the average level of the enterprises selected by Samsung, so the results achieved after 3 months is incredible. The factory is now more refined with more efficient production and more confident personnel. Previously, some customers wanted to cooperate with VIEMCO but evaluated the factory was not achieved, we would invite these customers return to visit, evaluate the factory, hope the current situation to meet their requirements and the contract will be signed”.

Program of improvement consultancy for supporting industrial enterprises co-organized by Samsung with Ministry of Industry and Trade since 2015; Up to now, there have been 32 enterprises in supporting industry receiving the consultancy across the country; A number of potential businesses have been selected as suppliers for Samsung. Enterprises that are not eligible to join the supply chain of the Korean manufacturer have also developed better, improving their competitiveness as well as finding new customers.

Wide door to join the supply chain

From experience of exporting goods to many partners in Europe, America, Mr. Tran Quoc Minh Dang, Director of Y Chi Viet Co., Ltd, said the foreign customers focusing on 2 things: enterprises must apply 5S well; having modern machinery and equipment and must ensure good product quality, consistency with competitive price. “We are constantly improving to stop going backward, the company now aims to cut down the rate of defective products to further improve production efficiency and keep prices competitive” – he Tran Quoc Minh Dang said.

According to the evaluation of Samsung, enterprises in the supporting industry of Vietnam in general have changed a lot in the past. Compared to 3 years ago, enterprises selected for improvement consultancy this year have more advanced machines and equipment, better production scale and organization. However, in order to maintain competitiveness and have the opportunity to participate in supply chains, the businesses need to maintain continuous improvement and change thinking in the direction that nothing is impossible if having right method.

Mr. Jung Munjo, Samsung expert, said that the businesses often encounter difficulties in maintaining improvement. “Enterprises must set goals, progress and check and supervise the implementation as well as the results achieved. There will be new companies with higher production levels, better product quality, more competitive prices appearing each day, the enterprises want to keep and develop orders or find more new customers, they must improve and do better every day to make customers more satisfied”- Mr. Jung Munjo analysis.

According to Mr. Jung Munjo, businesses should not put too much emphasis on the issue of being chosen to supply Samsung or not, but should focus on perfecting the business system, management activities to build larger and capable enterprises to cooperate with global supply chains. In addition to Samsung, there are Toyota and many other big manufacturers, so opportunities are always open for businesses with sufficient capacity and determination.